How Screw Pumps Increase Pressure in Industrial Applications

By:Admin

Introduction (124 words):

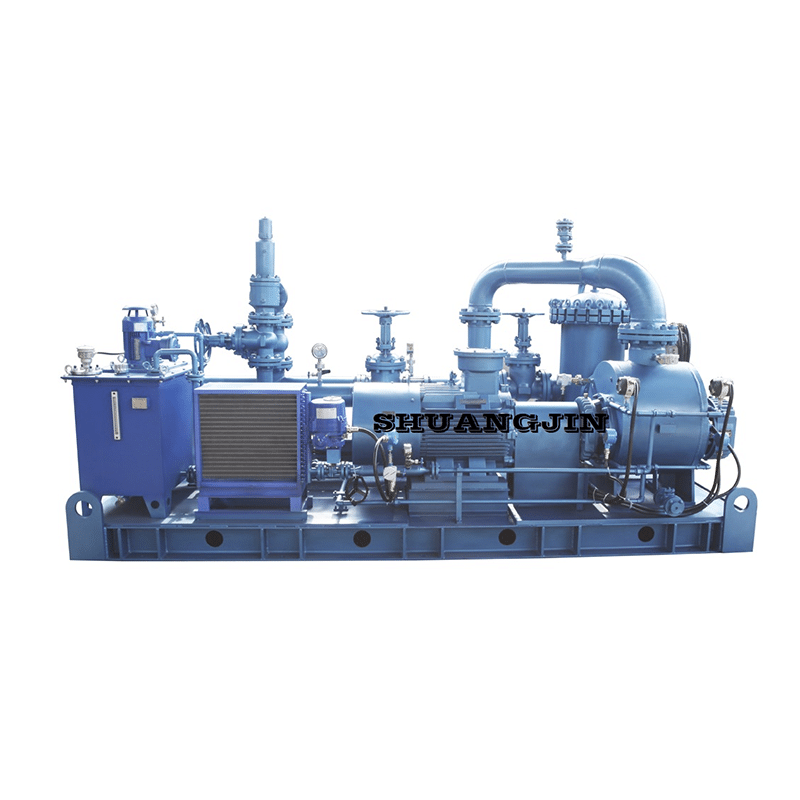

With rapid advancements in industrial technology, the demand for efficient fluid conveyance systems has become more crucial than ever. Recognizing this need, innovative engineering company [Company Name] has unveiled their latest solution—an advanced Screw Pump Pressure System. Boasting remarkable reliability, versatility, and industry-leading performance, this cutting-edge system is set to revolutionize fluid conveyance across various industries. Designed with state-of-the-art technologies and engineering expertise, the [Company Name]'s Screw Pump Pressure System is a game-changer in terms of operational cost-efficiency, maintenance, and overall productivity. Let us delve into the remarkable features and benefits of this groundbreaking solution.

Title: Enhanced Reliability and Durability

(136 words)

The Screw Pump Pressure System, developed by [Company Name], is engineered to deliver enhanced reliability and durability in industrial fluid conveyance operations. Through thorough research and rigorous testing, this revolutionary system has proven itself capable of withstanding high-pressure and high-viscosity fluid transportation. Utilizing advanced materials and cutting-edge engineering techniques, the system is built to withstand demanding industrial environments, minimizing downtime and increasing overall productivity.

Designed with precision components and assembled with meticulous attention to detail, the Screw Pump Pressure System offers unparalleled performance and durability. From challenging offshore oil drilling operations to intricate chemical processing, this system can handle a wide range of demanding tasks, ensuring smooth fluid conveyance even in the harshest conditions. Its robust design ensures long service life, reducing maintenance costs and maximizing uptime for businesses in need of reliable and high-performance fluid conveyance solutions.

Title: Versatile Fluid Handling Capabilities

(140 words)

One of the key highlights of the Screw Pump Pressure System developed by [Company Name] is its remarkable versatility in handling various types of fluids. Whether it is crude oil, lubricants, chemicals, or other viscous substances, this system guarantees efficient and reliable conveyance. With its ability to maintain a consistent flow, the Screw Pump Pressure System ensures minimal pulsation, ensuring smooth operations in critical applications.

Furthermore, this innovative solution offers adjustable speeds and pressure capabilities, allowing for increased flexibility in meeting diverse industrial requirements. By adapting to a wide range of fluid viscosities, the system can seamlessly integrate into various production processes, significantly improving overall operational efficiency. This adaptability extends to both horizontal and vertical fluid conveyance applications, making it a versatile choice for a wide range of industries, including oil and gas, chemical processing, wastewater treatment, and more.

Title: Unrivaled Performance and Cost Efficiency

(140 words)

The Screw Pump Pressure System developed by [Company Name] has set new benchmarks in terms of performance and cost efficiency. Equipped with precision-engineered screw rotors and advanced sealing technologies, this system ensures consistent flow rates, minimal leakage, reduced energy consumption, and optimal operational efficiency.

Thanks to its exceptional performance, the Screw Pump Pressure System boasts significant cost-saving advantages for businesses in the long run. Reduced energy consumption translates to lower operational costs, while the system's low-maintenance design minimizes downtime, boosts overall productivity, and improves return on investment. Moreover, the enhanced performance capabilities of this system enable businesses to optimize their manufacturing processes, achieve faster turnaround times, and meet increasing production demands.

Conclusion (112 words):

In conclusion, the Screw Pump Pressure System developed by [Company Name] presents a transformative solution to fluid conveyance challenges in various industries. Its remarkable reliability, versatile fluid handling capabilities, and unrivaled performance and cost efficiency set it apart from traditional systems. With its ability to withstand demanding environments and handle diverse fluid viscosities, this system is poised to revolutionize fluid conveyance operations, driving industrial productivity and profitability. [Company Name]'s commitment to innovation and advanced engineering exemplifies their dedication to providing cutting-edge solutions that cater to the evolving needs of modern industries.

Company News & Blog

Innovative Rotating Pump Technology Revolutionizes Water Management

Title: Revolutionary Rotating Pump Redefines Fluid Handling IndustryIntroduction:The fluid handling industry has experienced a groundbreaking innovation that is set to transform various sectors, including manufacturing, healthcare, and agriculture. A pioneering Rotating Pump, developed by an industry-leading company, has recently been unveiled, promising unparalleled efficiency, reliability, and versatility. This cutting-edge technology is set to revolutionize fluid handling operations and address the challenges faced by numerous industries across the globe.Background:With over [number] years of experience, the developers and engineers at [Company Name] have consistently pushed the boundaries of engineering excellence. Specializing in developing efficient and cutting-edge solutions, they have earned a reputation for delivering groundbreaking products. Their latest creation, the Rotating Pump, is no exception.Unveiling the Rotating Pump:The Rotating Pump offers a new and innovative approach to fluid handling by combining advanced technology, precision engineering, and unparalleled reliability. The pump's unique design enables it to handle a wide range of fluid types, including corrosive, viscous, and abrasive fluids, making it suitable for various industries.Efficiency and Versatility:Unlike traditional pumps, the Rotating Pump operates on an entirely different principle. By utilizing an innovative rotating mechanism that eliminates the need for rotating seals, the pump minimizes the risk of leakage and ensures superior efficiency. Additionally, it provides flexibility in fluid transfer operations, allowing for a seamless transition between different fluids without requiring significant downtime for cleaning and maintenance.Reliability and Durability:Designed with longevity in mind, the Rotating Pump boasts exceptional reliability and durability. Its robust construction, combined with high-quality materials, guarantees resistance to wear and tear, resulting in extended product lifespan and minimal maintenance requirements. This reliability ensures uninterrupted fluid handling operations for various industries, including chemical processing, pharmaceuticals, and food production.Superior Performance:The Rotating Pump's efficient design delivers outstanding performance metrics. Its innovative rotating mechanism enables it to handle high viscosity fluids without compromising flow rates, ensuring consistent and reliable performance even in challenging operating conditions. The pump's advanced control systems allow operators to fine-tune flow rates and pressure, providing precise adjustments tailored to specific operational requirements.Application in Multiple Industries:The Rotating Pump's versatility makes it an invaluable asset across various industries. In manufacturing, it enhances productivity by enabling efficient transfer and circulation of fluids within production lines. In healthcare, it ensures accurate dosing and transfer of pharmaceutical products, minimizing waste and potential contamination. Furthermore, the agricultural sector benefits from the pump's ability to handle viscous fertilizers and other critical fluid transfers with ease, streamlining operations and increasing productivity.Environmental Sustainability:Recognizing the importance of sustainable practices, the Rotating Pump is designed to minimize energy consumption and reduce environmental impact. By leveraging its advanced technology, the pump optimizes fluid handling processes, resulting in increased energy efficiency and reduced carbon footprint. This commitment to responsible manufacturing aligns with the global drive towards sustainable practices.Future Development:The developers at [Company Name] continue to refine and improve the Rotating Pump. Ongoing research and development efforts are focused on expanding its capabilities and addressing specific industry needs. The company's mission is to provide innovative fluid handling solutions that meet the ever-evolving requirements of a diverse range of industries.Conclusion:The introduction of the Rotating Pump marks a significant breakthrough in the fluid handling industry. By combining ingenuity, precision engineering, and environmental sustainability, this revolutionary technology has the potential to revolutionize fluid handling operations across various sectors. The unparalleled efficiency, reliability, and versatility of the Rotating Pump contribute to increased productivity, reduced downtime, and improved operational performance for industries worldwide.

Discover the Benefits of Using Industrial Screw Pumps for Pumping Applications

Title: Revolutionary Screw Pumps Set to Transform Industrial ProcessesIntroduction:In the ever-evolving world of industrial processes, one company is making headlines for its groundbreaking product: Screw Pumps. Designed to be efficient, reliable, and customizable, these pumps are set to revolutionize various sectors, from oil and gas to wastewater treatment. With their innovative features and advanced technology, Screw Pumps are quickly gaining recognition as the go-to solution for numerous industrial applications.Company Background and Vision:Established in {year of establishment}, {Company Name} has been at the forefront of innovation and engineering excellence for several decades. With a strong focus on research and development, the company has successfully introduced cutting-edge products and solutions to the market. Drawing on their extensive expertise, {Company Name} recognized the need for a more reliable and efficient pumping solution, leading to the development of Screw Pumps.The Revolutionary Design:The standout feature of Screw Pumps lies in their innovative screw technology. Unlike conventional pumps, Screw Pumps utilize a pair of intermeshing screws that rotate within a tightly sealed enclosure. This design not only eliminates the need for valves, pistons, and other moving parts but also drastically reduces energy consumption and maintenance requirements. The screws themselves are precision-engineered from high-quality materials, ensuring a longer lifespan and enhanced durability.Unparalleled Versatility:The versatility of Screw Pumps makes them suitable for a wide range of industrial applications. From oil refineries and petrochemical plants to food processing facilities and manufacturing plants, these pumps offer unparalleled performance and efficiency. They excel in handling both abrasive and non-abrasive fluids, such as crude oil, slurries, sewage, chemicals, and even high-viscosity liquids. The ability to handle such diverse applications makes Screw Pumps an ideal choice for industries worldwide.Energy Efficiency for Sustainability:One of the key advantages of Screw Pumps is their energy-efficient operation. By utilizing a low-shear process, these pumps greatly reduce energy consumption and contribute to a more sustainable future. Additionally, the absence of valves and pistons eliminates energy loss due to friction, resulting in substantial cost savings for industries. With environmental concerns becoming increasingly prominent, Screw Pumps offer an eco-friendly solution without compromising on performance.Enhanced Reliability and Lower Maintenance:Reliability is of utmost importance in any industrial process, and Screw Pumps deliver on that front. Thanks to their simple design and robust construction, these pumps require minimal maintenance and provide extended service life. The absence of valves and pistons translates to fewer components that can fail, reducing the risk of unplanned downtime and costly repairs. This reliability ensures uninterrupted operation, ultimately boosting the productivity and profitability of businesses.Customizable Solutions:Recognizing that different industries and processes require specific solutions, {Company Name} offers customized Screw Pump configurations tailored to meet individual requirements. This customization may include various material options, screw profiles, and pump sizes to optimize performance. By working closely with clients, {Company Name} ensures that the Screw Pumps not only meet but exceed their expectations, providing solutions that enhance efficiency and productivity.Conclusion:As industries continue to demand more efficient and sustainable solutions, Screw Pumps stand out as a game-changer. Combining their innovative design, energy efficiency, and reliability, these pumps have the potential to transform industrial processes across various sectors. With {Company Name} leading the way, businesses can now benefit from a cutting-edge pumping solution that boosts productivity, reduces environmental impacts, and ensures long-term success in the years to come.

Innovative Impeller Pump Design Revolutionizes Industrial Fluid Transfer

New Screw Impeller Pump Revolutionizes Industrial PumpingIndustrial processes require highly efficient and reliable pumping systems that can handle large volumes of liquids and solids. And, I am pleased to announce that the Screw Impeller Pump, produced by a leading manufacturer in the industry, delivers exactly that. The pump represents a technological revolution in the world of industrial pumping systems, and it has proved to be a game changer in harsh industrial environments across the globe.The Screw Impeller Pump, also known as the twin-screw pump, is a highly advanced pump that works on a unique screw impeller technology. The pump produces a smooth fluid flow while handling fluids with high viscosity, which is important in a variety of industrial applications. This is achieved by the co-rotating screws with a helical rotation that move precisely together and trap the fluid within the pump's cavity, moving it along steadily and continuously.The pump has been designed after decades of research and development on screw impeller technology. The pump manufacturer has implemented a patented technology that ensures that the Screw Impeller Pump performs exceptionally well in handling abrasive materials and viscous liquids that other pumps would typically struggle with. The technology involves an improved screw profile that helps to produce a more consistent flow rate, higher efficiency, and lower noise levels.To ensure that the Screw Impeller Pump meets the rigorous requirements of different industrial applications worldwide, the manufacturer has put a lot of effort into its construction. The pump features sturdy construction materials that resist wear, corrosion, and high-pressure surges. This makes it ideal for pumping fluids such as petroleum products, chemicals, paint, lubricants, and food products. The hard-wearing construction also ensures that the pump operates for longer periods without incurring downtime.The Screw Impeller Pump also comes with a highly advanced sealing system that prevents leaks, ensures that the pump's operation is smooth and stable, and reduces maintenance costs. This has been achieved by using a specially designed shaft seal that coats the shaft's surface with a low-friction coating that reduces friction. This feature significantly reduces the need for frequent maintenance and replacements.Another notable feature of the Screw Impeller Pump is its versatility. The pump can handle different types of fluids and materials and works well even in harsh industrial environments. It is also energy-efficient, which translates to reduced energy costs and lower carbon emissions. The pump consumes less energy to produce the same fluid volume as compared to conventional pumps, making it a great environmentally friendly alternative to traditional pumps.In addition to its excellent features, the Screw Impeller Pump delivers consistently high performance, thanks to its advanced monitoring and control systems. The manufacturer has incorporated advanced sensors and control systems that help to monitor the pump's performance in real-time. This ensures that the pump operates at its optimal level while preventing downtime and costly machine breakdowns.In summary, the Screw Impeller Pump is a high-performance industrial pump that has been designed to deliver exceptional performance in handling different types of fluids with various viscosities and solids. The pump's robust construction, advanced sealing system, and energy-efficient design make it a great addition to industrial process lines. Its versatility, consistency, and low maintenance costs make it a cost-effective solution to many industrial pumping challenges.As a renowned pump distributor, we are proud to offer this innovative pump to our clients across various industrial sectors. Get in touch with our experts today to learn more about the Screw Impeller Pump and how you can incorporate it into your industrial processes.

Innovative Triple Screw Pump Technology: Revolutionizing Industrial Fluid Transfer

Triple Screw Pump Offers High-Level Performance for Industrial Applications{Company Name} is proud to introduce the triple screw pump, a high-level performance solution for industrial applications. With the ability to handle viscous fluids while providing smooth and continuous flow, this reliable pump is ideal for a variety of industrial processes.One of the significant advantages of this pump is its high efficiency. It can achieve up to 90% efficiency while still being able to handle high-viscosity fluids such as crude oil, asphalt, and bitumen. This makes it an ideal solution for industries that require a high level of performance in their fluid handling processes.Another key feature of the triple screw pump is its ability to maintain consistent flow, even with varying inlet pressures. The screw design creates a clearing action within the pump, which means that there is a minimal risk of clogging or blockages, even with thicker fluids.The triple screw pump has been designed with ease of use in mind, making it an ideal choice for operators who need a low-maintenance solution. A self-priming design enables the pump to start and stop without the need for manual intervention, and it requires minimal disassembly for cleaning and servicing.Moreover, the pump has a compact footprint, which makes it easy to install and integrate into existing systems. Its low noise and vibration levels make it an ideal solution for applications where noise pollution and vibration could be an issue.It is recommended for industries that deal with liquid transfer, applications that need high pressure, high viscosity, and high temperature. Additionally, the triple screw pump is ideal for applications that involve feeding multiple points at once, as it can operate on a different number of pressures and flows.Furthermore, the triple screw pump is highly customizable, which means that it can be tailored to meet the specific needs of individual applications. Customization options include different materials of construction, various sealing systems, and different RPMs to suit the application's requirements.{Company Name} CEO, {Name}, stated "We are thrilled to offer this high-performance solution to our customers. The triple screw pump is an ideal choice for industries that require consistency and reliability in their fluid handling processes."In conclusion, the Triple Screw Pump offers high-level performance for industrial applications. With its high efficiency, consistent flow, low maintenance requirement, and customizable design, it is ideal for industries that deal with high-pressure, high-viscosity, and high-temperature applications. Operators can use it to feed multiple points at once while achieving a smooth and continuous flow.

Essential Guide to Different Types of Petroleum-Based Products

Title: Global Company Boosts Sustainability Efforts with Advanced Energy SolutionsIntroduction: In an endeavor to champion sustainable energy and reduce carbon emissions, {Company Name}, a leading global conglomerate, is expanding its portfolio by investing in advanced energy solutions. The company's latest move aims to strengthen its commitment to a greener future while diversifying its operations within the energy sector. By leveraging its extensive expertise in crude oil, fuel oil, cargo shipping, palm oil, pitch, asphalt, bitumen, and mineral resins, {Company Name} aims to drive significant positive change and contribute to a more sustainable world.Paragraph 1: Driving Sustainable Energy Transition{Company Name} recognizes the urgency to mitigate climate change while addressing global energy demands. As part of its sustainability strategy, the company is investing heavily in advanced energy solutions to facilitate a transition to renewable and low-carbon sources. By leveraging its vast experience in the crude oil industry, {Company Name} aims to harness the potential of emerging technologies, such as advanced biofuels and hydrogen, to promote a cleaner and more sustainable future.Paragraph 2: Clean Energy Revolution: Shifting from Fossil FuelsAcknowledging the critical need to diversify its energy sources, {Company Name} is actively exploring alternatives to conventional fossil fuels. While remaining committed to its core business of crude oil, the company is ramping up efforts to incorporate more sustainable practices and technologies. This includes researching and implementing fuel oil substitutes, such as biofuels and renewable energy sources, to reduce carbon emissions and create a more environmentally friendly energy matrix.Paragraph 3: Sustainable Cargo Shipping and Supply ChainAs a major player in the cargo shipping industry, {Company Name} is dedicated to making significant strides towards sustainability. The company's commitment extends to optimizing fuel consumption, reducing emissions, and employing eco-friendly vessels. By prioritizing the use of sustainable fuel alternatives in its shipping operations, such as biofuels, {Company Name} aims to minimize its carbon footprint and lead by example within the industry.Paragraph 4: Advancing the Biofuels IndustryRecognizing the potential of biofuels to revolutionize the energy landscape, {Company Name} is investing in research and development to enhance the efficiency and scale of biofuel production processes. Given its substantial expertise in palm oil cultivation and extraction, the company is exploring innovative ways to convert palm oil residue into biofuels, thereby reducing waste and maximizing resource utilization.Paragraph 5: Pioneering Infrastructure for Renewable Solutions{Company Name} is dedicated to accelerating the adoption of renewable energy resources and investing in the necessary infrastructure to support their integration into power grids. By expanding its involvement in the production and distribution of asphalt, bitumen, and mineral resins, the company is building a robust foundation for the implementation of renewable energy solutions, such as solar and wind farms.Conclusion: {Company Name}'s recent commitment to sustainable energy solutions signifies a pivotal moment in its history. By leveraging its extensive experience in crude oil, fuel oil, cargo shipping, palm oil, pitch, asphalt, bitumen, and mineral resins, the conglomerate is redefining its role within the energy sector. With a strong determination to drive the global shift to renewable energy, {Company Name} aims to set new industry standards and foster a sustainable future.

Discover the Distinctions Between Screw Pumps and Gear Pumps

Screw Pump and Gear Pump: Understanding the Differences in Pumping TechnologyPumping technology plays a crucial role in various industries, from manufacturing and oil and gas to wastewater treatment and food processing. For efficient and reliable pumping, two types of pumps that are often utilized are screw pumps and gear pumps. While both serve the purpose of moving fluids from one place to another, they differ in design and application. In this article, we will explore the differences between screw pumps and gear pumps.A screw pump, as the name suggests, operates by using rotating screws to move fluids from the inlet to the outlet. It consists of two or more intermeshing screws contained within a cylindrical or semi-cylindrical housing. The screws rotate in opposite directions, trapping the fluid between them and forcing it to move along the length of the screws. This type of pump is known for its gentle and smooth operation, making it ideal for handling shear-sensitive fluids or those containing small solids.On the other hand, a gear pump works by using two or more intermeshing gears to create a pumping action. The gears rotate in opposite directions, creating a partial vacuum at the inlet, which draws the fluid in, and then forces it out through the outlet. Gear pumps are characterized by their simplicity, compactness, and high-speed operation. They are commonly used for high-pressure applications, such as hydraulic systems, and for handling clean fluids with low viscosity.The key difference between these two types of pumps lies in their design and how they move fluids. Screw pumps use the rotating action of the screws to transport the fluid, while gear pumps rely on the intermeshing gears to create the necessary pumping action. This fundamental distinction affects the overall performance, efficiency, and suitability of each pump for specific applications.In terms of performance, screw pumps are known for their ability to handle viscous fluids and those with solids content. The continuous and smooth motion of the screws ensures minimal pulsations and provides a steady flow, making it suitable for applications where a consistent output is required. On the other hand, gear pumps excel in generating high-pressure output, making them ideal for applications that require pressurized fluid delivery. Their precise metering capabilities also make them suitable for applications that demand accurate flow control.When it comes to efficiency, screw pumps offer higher volumetric efficiencies compared to gear pumps. Due to their progressive cavity design, screw pumps can handle variable flow rates with minimal slip, ensuring a higher percentage of fluid is efficiently moved from the inlet to the outlet. Gear pumps, while generally less efficient, compensate with their compact size and ability to generate high pressure, making them suitable for space-constrained environments or applications with specific pressure requirements.In terms of application, screw pumps find extensive use in industries such as wastewater treatment, oil and gas, chemical processing, and food manufacturing. Their ability to handle high viscosity fluids, such as sludge, oil, and syrup, makes them suitable for these demanding environments. Gear pumps, on the other hand, are commonly employed in hydraulic systems, fuel transfer, lubrication systems, and various industrial processes that require high pressure and precise flow control.In conclusion, screw pumps and gear pumps are two distinct types of pumping technology, each with its own benefits and applications. Screw pumps offer gentle and steady fluid movement, making them well-suited for shear-sensitive fluids and those with solids content. Gear pumps, on the other hand, excel in generating high pressures and precise flow control, making them ideal for applications with specific pressure requirements. Understanding the differences between these two types of pumps can help industries make informed decisions when it comes to selecting the most suitable pumping technology for their specific needs.

Efficient Lube Oil System for Smooth Pump Operations

Title: Cutting-Edge and Reliable Lube Oil System for Pumps Revolutionizes the IndustryIntroduction (100 words):The rapidly growing industrial sector demands high-performance machinery that can operate optimally while minimizing downtime. To cater to this need, an innovative and pioneering engineering company has developed a state-of-the-art Lube Oil System for Pumps. This revolutionary system is designed to enhance the efficiency, reliability, and longevity of pumps in various industries, facilitating increased productivity and reduced maintenance costs. Capitalizing on advanced technology and unparalleled expertise, the pioneering company continues to redefine the standards of pump lubrication systems, catering to diverse industry needs worldwide.1. Superior Technology and Unmatched Performance (150 words):The Lube Oil System for Pumps represents a paradigm shift in the field of pump lubrication. Leveraging cutting-edge technology, this system ensures smoother pump operations, extending equipment life considerably. By addressing common issues such as overheating, leaks, and inefficient lubrication, the system enhances overall pump performance and reduces the risk of catastrophic failure.By utilizing precision-engineered components, the Lube Oil System guarantees an efficient and consistent lubrication process, providing optimal operational parameters. This results in reduced friction, improved energy efficiency, and increased service intervals, saving businesses significant costs on maintenance, repair, and replacement.Furthermore, the system's advanced filtration system removes impurities and contaminants, preventing abrasive particles from causing damage and ensuring prolonged pump lifespan. With its user-friendly design and intuitive interface, the system is easily integrated into existing infrastructure, catering to a wide range of pump sizes and types.2. Protection against Contamination and Corrosion (150 words):The Lube Oil System for Pumps places utmost emphasis on safeguarding the pumps against contamination and corrosion, which are major contributors to equipment malfunctions. By employing cutting-edge technologies such as corrosion inhibitors, the system effectively combats the damaging effects of corrosive substances, including water content typically found in lubricants.Furthermore, strategically positioned sensors and monitoring devices ensure early detection of potential pump malfunctions. These intelligent sensors continuously monitor vital parameters such as temperature, pressure, and flow rates, instantly alerting operators in case of any irregularities. Such proactive measures not only minimize unplanned shutdowns but also enable predictive maintenance, preventing costly equipment failures and optimizing operational efficiency.3. Customizable Solutions for Specific Industry Needs (150 words):Recognizing the diversity of industrial requirements, the Lube Oil System for Pumps offers a range of customizable solutions tailored to specific industry needs. Whether it is heavy-duty pumps utilized in the oil and gas industry, high-pressure pumps in the manufacturing sector, or industrial water pumps, the system ensures optimal lubrication and protection for pumps operating under extreme conditions.Moreover, this versatile system can be seamlessly integrated into both new installations and existing setups, offering a cost-effective solution for businesses across various sectors. The company's technical experts work closely with clients to understand their unique requirements, providing personalized solutions that align with their operational guidelines, regulatory requirements, and sustainability goals.4. Sustainability and Environmental Responsibility (150 words):The Lube Oil System for Pumps incorporates sustainable practices and responsible environmental management into its design. The system optimizes lubricant consumption, reducing waste and minimizing the carbon footprint associated with replacing lubricants frequently.Additionally, the advanced filtration system efficiently removes impurities and contaminants, reducing the ecological impact and promoting cleaner, greener operations. By extending the lifespan of pumps, the system also helps reduce waste generated from premature pump replacements.Furthermore, the system's energy-efficient design enhances overall plant efficiency, contributing to reduced energy consumption and promoting sustainable manufacturing practices.Conclusion (100 words):The groundbreaking Lube Oil System for Pumps ushers in a new era of reliability, performance, and sustainability in the pump lubrication domain. Its cutting-edge technology and customizable solutions cater to the diverse needs of industries worldwide, minimizing operational risks, optimizing production, and reducing maintenance costs. The company's unwavering commitment to delivering superior products and services continues to revolutionize the industry, ensuring a seamless integration of their systems into all types of pump installations. With an unblemished track record and a customer-centric approach, the company stands at the forefront of the pump lubrication sector, providing innovative solutions that set new benchmarks for excellence.

Exploring the Distinctions Between Screw Pumps and Gear Pumps – A Comprehensive Guide

Title: Decoding the Distinctions Between Screw Pumps and Gear PumpsIntroduction:In the world of fluid processing and transportation, pumps play a pivotal role in powering various industries such as oil and gas, pharmaceuticals, food processing, and many others. Screw pumps and gear pumps are two popular types of pumps used for handling different liquid mediums. Understanding the differences between these pumps is crucial in determining the most suitable choice for specific applications. This article aims to shed light on the dissimilarities between screw pumps and gear pumps, exploring their operating principles, advantages, and drawbacks.Section 1: The Operating Principles of Screw Pumps and Gear PumpsScrew pumps, also known as progressive cavity pumps, operate based on the principle of positive displacement. They consist of a rotating helical rotor that moves within a stationary double helical stator. As the rotor turns, cavities are formed and progress along the axis, pushing the liquid from the inlet to the outlet.On the other hand, gear pumps operate using the principle of positive displacement as well. They consist of two meshing gears, known as the driving gear and the driven gear, enclosed within a closely fitted housing. As the gears rotate, the liquid is trapped in the cavities between the teeth, creating a seal and forcing the liquid to move from the inlet to the outlet.Section 2: Advantages and Drawbacks of Screw Pumps and Gear Pumps2.1 Screw Pumps:Screw pumps offer several advantages, making them suitable for a wide range of applications. Firstly, they excel at handling high viscosity liquids and fluids with solid content. Thanks to their gentle pumping action, screw pumps are capable of handling shear-sensitive and abrasive fluids without compromising their integrity. Moreover, screw pumps provide a steady flow rate with minimal pulsation, ensuring smooth and consistent delivery. However, one drawback to consider is their relatively lower efficiency compared to gear pumps, resulting in higher energy consumption.2.2 Gear Pumps:Gear pumps offer their own set of advantages and drawbacks. One significant advantage of gear pumps is their ability to generate high pressures, especially in applications requiring high delivery heads. Additionally, gear pumps exhibit excellent self-priming capabilities, making them suitable for applications where a reliable suction source may be limited. However, gear pumps may struggle with handling highly viscous fluids and those containing solids. Their operation can also produce pulsations and pressure fluctuations, which can be detrimental to certain sensitive processes.Section 3: Applications and Industries3.1 Screw Pumps:Screw pumps find applications in numerous industries, such as oil and gas, wastewater treatment, and chemical processing. Their ability to handle high-viscosity fluids, combined with their gentle pumping action, makes them ideal for applications involving crude oil, sludge, and abrasive chemicals.3.2 Gear Pumps:Gear pumps find widespread use in industries such as automotive, pharmaceuticals, and food processing. The ability of gear pumps to generate high pressures and their self-priming capabilities make them suitable for applications involving lubricating oils, hydraulic fluids, and metering precise volumes of liquid.Conclusion:In conclusion, both screw pumps and gear pumps serve essential roles in fluid processing and transfer applications. Choosing the appropriate pump type depends on factors such as the viscosity of the liquid, presence of solids, required pressure, and the level of pulsation tolerance. Understanding the distinct operating principles, advantages, and drawbacks of screw pumps and gear pumps is crucial in selecting the right pump for specific industrial needs.

Why the Latest Innovation in Pump Technology is Revolutionizing the Oil Industry

[Suggested Introduction]In a groundbreaking development, a renowned company is set to revolutionize the industrial world with its latest offering, the Screw Oil Pump. This cutting-edge innovation is poised to transform oil extraction processes by improving efficiency and reducing environmental impact. With an unwavering commitment to sustainable practices, the company aims to set new benchmarks in the oil industry. In this article, we will delve deeper into the features and benefits of this state-of-the-art Screw Oil Pump, shedding light on its potential to reshape the entire sector.[Body]The Screw Oil Pump, developed by a trailblazing company with decades of experience in the oil industry, is a paradigm shift in oil extraction technologies. Leveraging their expertise, the company has designed and engineered this pump to enhance efficiency and sustainability. By seamlessly combining robust engineering principles with advanced technological innovations, they have created a product that addresses key challenges faced in the oil extraction process.At the heart of this innovation lies the unique design of the Screw Oil Pump, which optimizes the pumping mechanism for oil extraction. Unlike conventional pumps, this cutting-edge solution significantly reduces energy consumption, leading to substantial cost savings for oil producers. The pump's remarkable efficiency is achieved through a combination of precise engineering and the utilization of state-of-the-art materials, ensuring maximum output while minimizing energy wastage.Furthermore, the Screw Oil Pump is equipped with an intelligent control system that allows it to adapt to varying extraction conditions. Built-in sensors and proprietary algorithms enable the pump to continuously monitor and adjust operating parameters, ensuring optimal performance even in challenging environments. This not only improves productivity but also significantly reduces downtime and maintenance requirements, resulting in further cost savings for oil producers.In addition to its economic benefits, the Screw Oil Pump prioritizes environmental sustainability. Industry-related carbon emissions and their impact on the environment have long been a concerning issue. However, this revolutionary pump incorporates advanced technologies to minimize its carbon footprint. By employing efficient motors and leveraging smart controls to optimize energy consumption, the pump enables oil producers to contribute to a greener future while maintaining their operational efficiency.Moreover, the Screw Oil Pump is designed with longevity in mind. Recognizing the importance of durability in the industrial sector, the company has used only the highest-quality materials and components to ensure product reliability and extended lifespan. By doing so, they reduce the need for frequent replacements and repairs, further contributing to cost-effectiveness and sustainable operations.Another distinctive feature of the Screw Oil Pump is its versatility. The pump can be seamlessly integrated into existing oil extraction systems, ensuring a smooth transition and ease of implementation for oil producers. This compatibility eliminates the need for extensive modifications, saving both time and resources for companies adopting this innovative solution.As the world continues to shift towards renewable energy sources, the sustainability and efficiency of traditional energy industries, such as oil extraction, become increasingly crucial. The Screw Oil Pump presents an opportunity for oil producers to keep pace with the evolving energy landscape and simultaneously address concerns related to cost, efficiency, and environmental impact.The combination of cutting-edge technology, energy efficiency, sustainability, and ease of integration positions the Screw Oil Pump as a game-changer in the oil extraction industry. With its potential to revolutionize operations and secure a more sustainable future, the pump has garnered immense interest from industry experts and professionals alike.[Conclusion]As the global demand for oil and energy continues to rise, it is imperative for the industry to embrace innovative solutions that propel us towards a more sustainable future. The Screw Oil Pump, with its remarkable efficiency, environmental consciousness, and adaptability, presents an exciting opportunity for oil producers worldwide. By reducing energy consumption, optimizing performance, and prioritizing sustainability, this groundbreaking pump is poised to redefine the way oil extraction is carried out. Embracing this ingenious solution can not only benefit individual companies but also contribute to the larger goal of achieving a greener and more sustainable energy sector.

Exploring the Versatility of Screw Pumps - Unraveling the Inner Workings of Centrifugal Designs

Centrifugal Screw Pump Revolutionizes Fluid Transfer: Introducing a Game-Changing Device by Leading Pump Manufacturer[Company Name], a renowned manufacturer in the fluid transfer industry, has recently unveiled their latest innovation – the Centrifugal Screw Pump. This groundbreaking device promises to revolutionize fluid transfer processes across various sectors, offering improved efficiency, reliability, and ease of use.The Centrifugal Screw Pump is a result of meticulous research and development by [Company Name], a company with a longstanding reputation for delivering high-quality fluid transfer solutions. With a rich history spanning several decades, [Company Name] has continuously strived to push the boundaries of innovation in the pump manufacturing field.The Centrifugal Screw Pump is designed to address the challenges faced by industries dependent on smooth fluid transfer operations. Its cutting-edge technology combines the benefits of centrifugal force and screw pumping mechanisms, resulting in a device that boasts excellence in both performance and versatility.One of the key features of the Centrifugal Screw Pump is its ability to handle a wide range of fluids, including those with high viscosity and entrained solids. This adaptability makes it ideal for applications across a multitude of industries, such as oil and gas, chemical processing, power generation, and wastewater treatment.The unique design of the Centrifugal Screw Pump allows for enhanced operational efficiency. Its innovative screw impeller ensures a smooth and consistent flow rate, minimizing the risk of pulsation and cavitation. This feature not only increases productivity but also prolongs the lifespan of the pump, reducing maintenance costs for businesses.Moreover, the Centrifugal Screw Pump offers significant energy savings compared to traditional fluid transfer devices. Its advanced motor design, combined with a robust impeller structure, reduces power consumption while delivering optimal performance. This translates into reduced operational costs and a smaller environmental footprint, aligning with the global push towards sustainability.Furthermore, the Centrifugal Screw Pump is engineered for easy installation and maintenance. Its compact and modular design simplifies on-site assembly, minimizing downtime during installation. Additionally, the pump's user-friendly interface provides operators with real-time performance metrics and alerts, facilitating proactive troubleshooting and ensuring consistent operation.Safety is also prioritized with the Centrifugal Screw Pump, as it incorporates various features to mitigate risks. Equipped with advanced sensors, the pump actively monitors temperature, pressure, and other parameters, automatically shutting down in case of system anomalies. This proactive approach not only protects valuable assets but also prevents accidents and ensures operator well-being.The Centrifugal Screw Pump comes backed by [Company Name]'s extensive customer support and service network. With a global footprint and a commitment to customer satisfaction, the company offers comprehensive technical assistance, spare parts availability, and prompt maintenance services. This ensures that businesses using the Centrifugal Screw Pump can rely on uninterrupted operations and optimal performance.As [Company Name] continues to advance the boundaries of pump manufacturing and revolutionize the fluid transfer industry, they solidify their position as a pioneer in the field. The Centrifugal Screw Pump stands as a testament to their dedication to innovation, efficiency, and customer-centricity, offering businesses a game-changing solution for their fluid transfer needs.In conclusion, the introduction of the Centrifugal Screw Pump by [Company Name] is set to transform fluid transfer processes across industries. With its exceptional performance, versatility, energy efficiency, and user-friendly features, this revolutionary pump device promises to enhance productivity, reduce operational costs, and contribute to a more sustainable future.