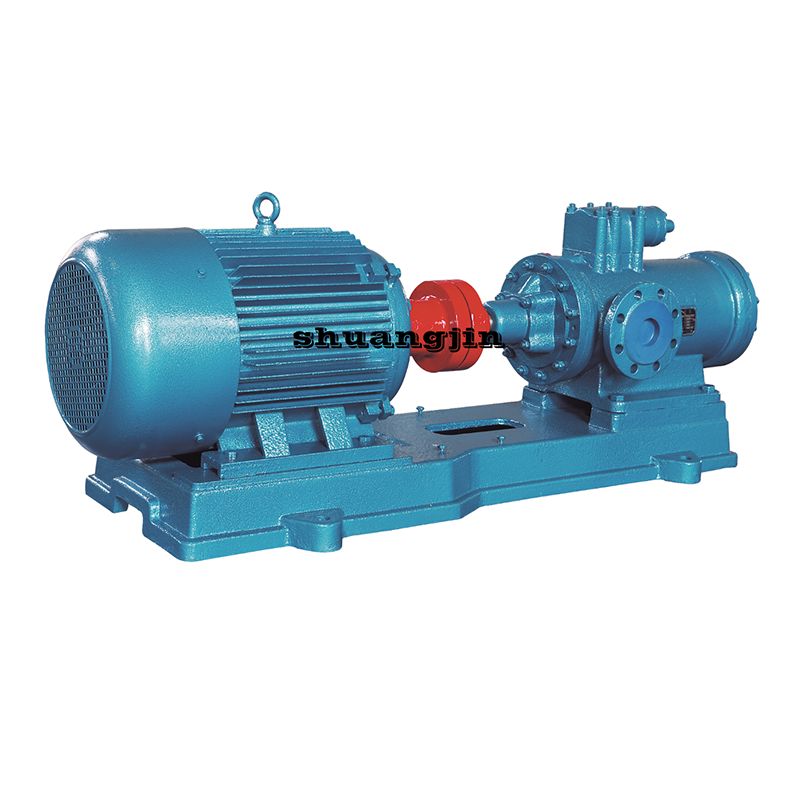

High-Quality Water Pump for Gears: A Must-Have for Your Equipment

By:Admin

The company specializes in designing and manufacturing a wide range of gear water pumps that are used in various applications such as agriculture, construction, mining, and industrial processes. Their pumps are known for their durability, efficiency, and ability to handle tough operating conditions.

Gear Water Pump's success can be attributed to its state-of-the-art manufacturing facilities, stringent quality control processes, and a skilled team of engineers and technicians who are dedicated to delivering superior pump solutions. The company's unwavering focus on research and development has allowed it to stay ahead of the curve in terms of technology and innovation, ensuring that its products meet the evolving needs of its customers.

In addition to its standard product offerings, Gear Water Pump also provides customized pump solutions to meet specific application requirements. Whether it's a unique size, material, or performance specification, the company's engineering team works closely with customers to design and deliver tailored pump solutions that meet their exact needs.

One of the key factors that sets Gear Water Pump apart from the competition is its strong commitment to customer service. The company takes pride in its ability to provide prompt and reliable support to its customers, whether it's technical assistance, product information, or after-sales service. This dedication to customer satisfaction has helped build long-lasting relationships with a wide range of clients, including OEMs, distributors, and end-users.

Despite its already strong position in the market, Gear Water Pump continues to invest in its future growth and success. The company is constantly exploring new technologies, materials, and manufacturing processes to enhance the performance and reliability of its products. Additionally, it actively seeks out opportunities to expand its presence in new markets and industries, both domestically and internationally.

Recently, Gear Water Pump has introduced a new line of gear water pumps that incorporates the latest advancements in pump technology. These pumps feature improved efficiency, durability, and performance, making them ideal for demanding applications. The company's dedication to innovation has once again set a new standard in the industry, further solidifying its position as a leading provider of water pump solutions.

In line with its commitment to sustainability and environmental responsibility, Gear Water Pump is also developing eco-friendly pump solutions that reduce energy consumption and minimize environmental impact. By staying ahead of regulatory trends and customer demands, the company is positioning itself as a responsible and forward-thinking partner for its clients.

Looking ahead, Gear Water Pump remains focused on its core values of quality, innovation, and customer satisfaction. With a solid foundation and a clear vision for the future, the company is poised to continue its success in the pump industry and remain a trusted partner for its clients. Whether it's for standard pump solutions or custom-designed products, Gear Water Pump stands ready to meet the water pump needs of industries around the world.

Company News & Blog

Top Industrial Vacuum Pump Options for 2022

Industrial Vacuum Pump is revolutionizing the manufacturing industry with its innovative and high-performance vacuum pumps. These pumps are designed to meet the demanding needs of various industries, including automotive, food and beverage, pharmaceutical, and more. With their advanced technology and precision engineering, Industrial Vacuum Pump is the go-to solution for companies looking to enhance their production processes and efficiency.Founded in 1998, Industrial Vacuum Pump has built a reputation for excellence in the field of vacuum pump manufacturing. The company has a state-of-the-art manufacturing facility with a team of highly skilled engineers and technicians who are dedicated to producing top-quality vacuum pumps. With an emphasis on research and development, Industrial Vacuum Pump continuously strives to stay ahead of the curve in terms of technology and innovation.One of the key factors that sets Industrial Vacuum Pump apart from its competitors is its commitment to quality and reliability. The company adheres to strict quality control measures at every stage of the manufacturing process to ensure that each vacuum pump meets the highest standards. This dedication to quality has earned Industrial Vacuum Pump the trust and loyalty of its customers worldwide.Industrial Vacuum Pump offers a wide range of vacuum pumps to cater to the diverse needs of its clients. From dry screw vacuum pumps to oil-sealed rotary vane pumps, the company's product lineup is designed to deliver exceptional performance and efficiency. These pumps are capable of handling a variety of applications, including vacuum packaging, material handling, degassing, and more.Moreover, Industrial Vacuum Pump's dedication to customer satisfaction is evident in its comprehensive after-sales support. The company provides expert technical support and maintenance services to ensure that its customers' vacuum pumps continue to operate at peak performance. This commitment to customer service has made Industrial Vacuum Pump a trusted partner for businesses around the globe.In addition to its product excellence, Industrial Vacuum Pump is also committed to environmental sustainability. The company understands the importance of minimizing its environmental footprint and, as such, it strives to develop energy-efficient vacuum pumps that reduce power consumption and waste. Furthermore, Industrial Vacuum Pump is dedicated to waste reduction and recycling initiatives within its manufacturing processes.The success of Industrial Vacuum Pump can be attributed to its unwavering commitment to innovation, quality, and customer satisfaction. The company's continuous efforts to push the boundaries of vacuum pump technology have positioned it as a global leader in the industry. With a strong focus on research and development, Industrial Vacuum Pump is poised to continue setting new benchmarks for excellence in the manufacturing sector.Looking to the future, Industrial Vacuum Pump aims to further expand its global presence and reach new markets. The company is committed to staying at the forefront of technological advancements and providing cutting-edge solutions to meet the evolving needs of industries worldwide. With a clear vision and a dedication to excellence, Industrial Vacuum Pump is set to continue revolutionizing the manufacturing industry for years to come.In conclusion, Industrial Vacuum Pump has established itself as a leading provider of high-performance vacuum pumps. With a relentless focus on quality, innovation, and customer satisfaction, the company has earned the trust of businesses worldwide. As it continues to push the boundaries of vacuum pump technology, Industrial Vacuum Pump is well-poised for a future of continued success and excellence.

Guide to Pump Lube Oil and Its Importance

[Company Introduction]Established in 1998, our company has been dedicated to providing high-quality industrial lubricants to various industries around the world. Our product line includes a wide range of lubricants, including hydraulic oils, gear oils, compressor oils, and specialty lubricants for specific applications. With a focus on quality, innovation, and customer satisfaction, we have built a strong reputation as a trusted provider of lubrication solutions.[News Content]Pump Lube Oil is a critical component in the operation of industrial pumps, ensuring smooth and efficient performance while reducing wear and tear on the equipment. As a leading supplier of industrial lubricants, our company is proud to introduce our new and improved Pump Lube Oil, designed to meet the demanding requirements of modern pumping systems.The new Pump Lube Oil is specially formulated to provide superior protection and performance in a wide range of pump applications, including centrifugal pumps, positive displacement pumps, and other types of industrial pumping equipment. Its advanced formula offers excellent thermal stability, oxidation resistance, and anti-wear properties, making it ideal for use in challenging operating conditions.One of the key features of our new Pump Lube Oil is its exceptional film strength, which helps to reduce friction and wear on critical pump components such as bearings, gears, and seals. This not only extends the service life of the pumps but also improves their overall efficiency, resulting in energy savings and reduced maintenance costs for our customers.Furthermore, the new Pump Lube Oil is designed to provide excellent water separation and demulsibility, ensuring reliable performance in applications where water contamination is a concern. This feature is particularly important in industries such as wastewater treatment, mining, and marine, where pumps are often exposed to water and other contaminants that can compromise lubricant performance.In addition to its outstanding performance characteristics, our new Pump Lube Oil is also environmentally friendly, formulated with high-quality base oils and additives that offer excellent biodegradability and low toxicity. This ensures that our lubricant meets the strict environmental regulations and standards, while also promoting a safer and healthier work environment for our customers and their employees.To further support our customers, we offer comprehensive technical support and lubrication management services to help them optimize the performance and reliability of their pumping systems. Our team of experienced lubrication engineers can provide valuable insights and recommendations on lubricant selection, application, and maintenance, ensuring that our customers get the most out of their investment in our products.In conclusion, the introduction of our new and improved Pump Lube Oil reaffirms our commitment to delivering innovative and high-quality lubrication solutions to our customers. With its superior performance, environmental friendliness, and comprehensive support services, our Pump Lube Oil is set to become the lubricant of choice for industrial pump applications worldwide. We are confident that this new product will help our customers improve the reliability, efficiency, and sustainability of their pumping operations, while reducing overall operating costs and environmental impact.

Maximizing Efficiency of Screw Pumps: Tips and Techniques

Screw Pump Efficiency Revolutionizes the Pumping IndustryIn the world of industrial pumping, efficiency is everything. And one company has been leading the charge in revolutionizing pump efficiency with their innovative screw pump technology.For decades, the pumping industry has relied on traditional centrifugal pumps to move liquids and gases in various industrial applications. While these pumps have served their purpose, they often come with inefficiencies and limitations that can affect their performance and productivity. This is where the screw pump, a game-changing alternative, comes into play.With its unique design and capabilities, the screw pump has proven to be a more efficient and reliable option for a wide range of industrial pumping tasks. Unlike traditional centrifugal pumps, screw pumps are able to handle high viscosity liquids, solids, and abrasive materials with ease. This makes them ideal for demanding applications such as oil and gas, chemical processing, wastewater treatment, and marine industries.One company at the forefront of this screw pump revolution is [Company Name]. With a history dating back to [year], [Company Name] has been a leading manufacturer and supplier of screw pumps and other pumping solutions for a diverse range of industries. Their commitment to innovation and customer satisfaction has earned them a reputation for excellence in the pumping industry.[Company Name]’s screw pumps are designed with efficiency and performance in mind. Their unique helical rotor design allows for smooth and continuous pumping of a wide variety of fluids, resulting in higher flow rates and lower energy consumption. This not only saves on operational costs but also reduces downtime and maintenance requirements, making their screw pumps a cost-effective and reliable choice for industrial pumping needs.Furthermore, [Company Name] offers a range of customizable options and accessories for their screw pumps, allowing customers to tailor their pumping solutions to their specific requirements. Whether it’s different materials of construction, sizes, or configurations, [Company Name] ensures that their screw pumps meet the unique needs of each customer and application.In addition to their innovative products, [Company Name] is committed to providing exceptional customer service and support. Their team of experts works closely with customers to understand their pumping challenges and provide tailored solutions that maximize efficiency and performance. From initial consultation to installation and ongoing maintenance, [Company Name] is dedicated to being a trusted partner for all of their customers’ pumping needs.With a strong focus on research and development, [Company Name] continues to push the boundaries of screw pump technology. Their investment in cutting-edge design and engineering ensures that their products remain at the forefront of pump efficiency and reliability, setting new standards in the industry.The success of [Company Name] and their screw pump technology has not gone unnoticed. They have garnered a loyal customer base and earned numerous accolades and certifications for their commitment to quality and innovation. Their dedication to sustainable and environmentally friendly pumping solutions has also positioned them as a leader in the industry.As the industrial pumping industry continues to evolve, efficiency and reliability will remain key factors in determining the success of pumping solutions. With their innovative screw pump technology and commitment to customer satisfaction, [Company Name] is well-positioned to lead the way in revolutionizing the pumping industry for years to come.

Essential Tips for Maintaining Your Screw Pump

Screw Pump Maintenance: Keeping the Flow SmoothScrew pumps are indispensable in various industrial applications, including oil and gas, pulp and paper, chemical processing, and marine industries. These pumps play a critical role in transferring liquids or semi-solids efficiently. However, to ensure their reliable performance, routine maintenance is crucial.{Company Name} is a leading provider of screw pump maintenance services, offering comprehensive solutions to keep the flow smooth for its clients. With a dedicated team of experienced technicians and a commitment to quality, {Company Name} has built a reputation for excellence in the industry.As a specialist in screw pump maintenance, {Company Name} understands the importance of regular upkeep to prevent costly downtime and equipment failures. The company offers a range of maintenance services designed to prolong the life of screw pumps and optimize their performance.One of the key maintenance tasks for screw pumps is the inspection and replacement of wearing parts. Over time, the screws, shafts, and bearings in a screw pump can experience wear and tear, leading to decreased efficiency and potential breakdowns. {Company Name} provides thorough inspections to identify any worn or damaged parts and offers timely replacements to ensure the pump operates at peak performance.In addition to parts replacement, lubrication is another essential aspect of screw pump maintenance. Proper lubrication is critical for reducing friction and heat generation within the pump, which can significantly impact its efficiency and longevity. {Company Name} uses high-quality lubricants and follows manufacturer recommendations to ensure that screw pumps are adequately lubricated for optimal operation.Furthermore, {Company Name} provides alignment and vibration analysis services to identify any potential issues that could affect the performance of screw pumps. Misalignment or excessive vibration can lead to premature wear and component damage, so the company's comprehensive maintenance approach includes proactive measures to address these concerns.{Company Name} also offers troubleshooting and repair services for screw pumps experiencing operational issues. With their depth of expertise, their technicians can quickly diagnose problems and implement effective solutions to get the pump back up and running.In addition to routine maintenance, {Company Name} emphasizes the importance of proactive maintenance planning for screw pumps. By developing customized maintenance schedules based on the specific operating conditions and demands of each client, the company helps to minimize the risk of unexpected failures and costly repairs.As part of their commitment to excellence, {Company Name} also provides training and support to their clients' maintenance and operations teams. By sharing their knowledge and best practices, they empower their clients to take a proactive approach to screw pump maintenance, ultimately extending the lifespan of their equipment and optimizing their investment.With a track record of delivering reliable and cost-effective maintenance solutions, {Company Name} has earned the trust of a diverse range of industries that rely on screw pumps for their operations. Whether it's ensuring the smooth flow of oil and gas, the efficient transfer of chemicals, or the reliable dewatering of pulp and paper products, the company's expertise in screw pump maintenance has made them a preferred partner for many businesses.In conclusion, screw pump maintenance is essential for sustaining the performance of these critical pieces of equipment. {Company Name} stands out as a trusted provider of comprehensive screw pump maintenance services, offering a holistic approach to ensure that their clients' screw pumps operate smoothly and efficiently. With their commitment to quality, expertise, and customer satisfaction, {Company Name} continues to be a leader in the field of screw pump maintenance.

Discover the Benefits of Efficient Electric Heating Pumps in Home Heating Systems

Title: Innovative Electric Heating Pump Revolutionizes Energy EfficiencyIntroduction:In today's world, where energy conservation and sustainable practices are crucial, one company is spearheading a remarkable advancement in heating technology. {Company Name}, a leading innovator in the field, has recently unveiled their groundbreaking Electric Heating Pump, poised to revolutionize energy efficiency.The Electric Heating Pump:Designed to provide both heating and cooling solutions for residential and commercial buildings, the Electric Heating Pump breaks new ground with its advanced functionality and eco-friendly design. By utilizing cutting-edge technology, this pump offers a highly efficient and cost-effective alternative to traditional heating systems.Operating Principle:The Electric Heating Pump employs a heat transfer process that extracts heat energy from the ambient air, enabling it to provide heating during colder months. It works on the same principle as a refrigerator, but in reverse. By absorbing heat from the surrounding environment, it elevates the temperature and releases warm air into the building, ensuring a comfortable living or working space.Key Features:1. Energy Efficiency: The Electric Heating Pump significantly reduces energy consumption by utilizing the heat present in the air, making it up to three times more energy-efficient than conventional heating methods. It helps users achieve substantial savings on their energy bills while protecting the environment.2. Versatility: Apart from providing efficient heating, the Electric Heating Pump also doubles as an air conditioner during warmer months. This versatile feature ensures year-round comfort, regardless of the season.3. Smart Technology Integration: Equipped with smart controls, the Electric Heating Pump allows users to effortlessly customize temperature settings according to their preferences. This user-friendly interface ensures optimized efficiency and convenience.4. Silent Operation: Designed with noise reduction features, the Electric Heating Pump operates silently, eliminating the annoyance of loud fans or compressors typically associated with traditional heating systems.Addressing Climate Change:As the world grapples with the increasingly pressing issue of climate change, technologies like the Electric Heating Pump play a pivotal role in transitioning to sustainable practices. By reducing greenhouse gas emissions and relying on the freely available heat energy in the environment, the pump aligns with global efforts to combat climate change.Company Name's Commitment:{Company Name} is at the forefront of driving sustainable solutions, developing pioneering products that contribute to energy conservation and environmental protection. With over {number} years of expertise in the industry, the company combines innovative engineering and a commitment to customer satisfaction to deliver state-of-the-art technology.Market Impact:The introduction of the Electric Heating Pump is set to disrupt the heating industry by setting new standards in energy efficiency. By offering an alternative to traditional heating systems, this advanced technology ensures reduced carbon footprints while delivering significant savings to consumers.Conclusion:In a world that demands energy-efficient and sustainable solutions, the Electric Heating Pump offers a game-changing heating and cooling solution. {Company Name's} commitment to developing innovative technologies not only enhances consumer comfort but also contributes to a greener, more sustainable future. With the Electric Heating Pump, efficiency, convenience, and environmental consciousness merge, setting a new benchmark in the industry.

High-performance Positive Displacement Oil Pump: A Guide to Efficient Oil Pumping

Positive Displacement Oil Pump Revolutionizes Industrial Pumping TechnologyIn the world of industrial pumping, efficiency and reliability are crucial factors for success. This is where the positive displacement oil pump from [Company Name] comes into play, bringing a whole new level of performance and capability to the industry. With its innovative design and cutting-edge technology, this pump has quickly become the go-to solution for companies looking to optimize their pumping operations.[Company Name] has been a leader in the pumping industry for over 30 years, providing high-quality and reliable pumping solutions to a wide range of industries. With a strong focus on innovation and continuous improvement, the company has developed a reputation for delivering top-of-the-line products that meet the unique needs of its customers.The positive displacement oil pump is the latest addition to [Company Name]'s extensive product lineup, and it has quickly made a name for itself as a game-changer in the industry. What sets this pump apart from traditional pumping solutions is its innovative positive displacement technology, which allows for a more precise and consistent flow of oil.This technology is based on the principle that the pump displaces a specific amount of fluid with each revolution, ensuring a constant and reliable flow of oil. This is in stark contrast to traditional pumps, which rely on centrifugal force to move the fluid, leading to fluctuations in flow and efficiency.The positive displacement oil pump from [Company Name] is designed to offer superior performance and efficiency, making it an ideal choice for a wide range of industrial applications. Whether it's in the automotive, manufacturing, or oil and gas industries, this pump has proven to be a reliable and cost-effective solution for companies looking to optimize their pumping operations.One of the key advantages of this pump is its ability to handle a wide range of viscosities, making it suitable for pumping a variety of oils and lubricants. This versatility makes it a valuable investment for companies that deal with different types of fluids in their operations.Another major benefit of the positive displacement oil pump is its durability and low maintenance requirements. Thanks to its robust design and high-quality materials, this pump is built to withstand the rigors of industrial use, minimizing downtime and reducing the need for frequent repairs and maintenance.Furthermore, the pump's compact and efficient design makes it easy to install and integrate into existing pumping systems, providing a seamless and hassle-free retrofit solution for companies looking to upgrade their operations.[Company Name] takes pride in its commitment to providing exceptional customer service and support. This extends to the positive displacement oil pump, with the company offering comprehensive maintenance and technical support to ensure that customers get the most out of their investment.The positive displacement oil pump from [Company Name] has quickly gained recognition for its performance and reliability, earning the trust of customers across the globe. Its innovative design and advanced technology have set a new standard for industrial pumping solutions, providing companies with a valuable tool to optimize their operations and improve efficiency.As the industry continues to evolve, [Company Name] remains at the forefront of innovation, constantly pushing the boundaries of what is possible in industrial pumping technology. With its positive displacement oil pump, the company has once again demonstrated its commitment to delivering cutting-edge solutions that meet the evolving needs of its customers.In conclusion, the positive displacement oil pump from [Company Name] is a true game-changer in the world of industrial pumping. With its innovative design, superior performance, and unmatched reliability, this pump has set a new standard for what companies can expect from their pumping solutions. As the industry continues to evolve, [Company Name] remains dedicated to providing top-of-the-line products that empower companies to optimize their operations and achieve new levels of success.

New Gas Pump Technology Promises More Fuel Efficiency and Faster Refueling

CTP Pump, leading supplier of industrial pumps and equipment, has announced an expansion of their product line to meet the growing demand for innovative and efficient pumping solutions in the manufacturing and processing industries.With a focus on providing high-quality and reliable products, CTP Pump has been a trusted supplier to a wide range of industries for over 30 years. The company offers a comprehensive range of pumping solutions, including centrifugal pumps, diaphragm pumps, and gear pumps, as well as a variety of accessories and components to meet the specific needs of their customers.In response to the increasing demand for advanced pumping technology, CTP Pump has introduced a new line of innovative and efficient pumps that are designed to improve performance, reduce energy consumption, and lower operating costs. These new products have been developed in collaboration with leading industry experts and are backed by extensive research and development to ensure they meet the highest standards of quality and reliability.The new product line includes a range of high-efficiency centrifugal pumps that are designed to deliver superior performance and energy savings. These pumps are equipped with state-of-the-art technology, such as advanced impeller designs and precision-engineered components, to provide optimal flow rates and pressure levels while minimizing maintenance requirements and downtime.In addition to centrifugal pumps, CTP Pump has also expanded their portfolio to include a new series of diaphragm pumps that are specifically designed to handle a wide range of fluids, including corrosive and abrasive materials. These pumps feature a rugged and durable construction, as well as innovative diaphragm designs that ensure reliable and consistent performance in the most demanding applications.Furthermore, CTP Pump has introduced a new line of gear pumps that are engineered for efficient and reliable operation in a variety of industrial and commercial settings. These pumps are designed to deliver precise and consistent flow rates, as well as high levels of durability and longevity to meet the needs of their customers.As a leading supplier of industrial pumps and equipment, CTP Pump is committed to providing comprehensive solutions to help their customers improve their operational efficiency and productivity. The company's team of experienced engineers and technicians are available to support their customers throughout every step of the pump selection, installation, and maintenance process.In addition to their extensive product line, CTP Pump offers a variety of services, including technical support, maintenance and repair, and customized pumping solutions to meet the specific needs of their customers.With the introduction of their new product line, CTP Pump is poised to further strengthen their position as a trusted provider of innovative and efficient pumping solutions for the manufacturing and processing industries. The company's commitment to quality, reliability, and customer satisfaction makes them the preferred choice for businesses looking to enhance their pumping operations.For more information about CTP Pump and their range of industrial pumping solutions, visit their website or contact their sales team to discuss specific requirements and learn more about the benefits of their new product line.

Top Pump Manufacturer Announces New Product Release

Netzsch Pump, a leading manufacturer of industrial pumps, has recently introduced a new line of innovative pumping solutions designed to meet the evolving needs of the global industrial market. With a legacy of over 60 years in the industry, Netzsch Pump has continuously pushed the boundaries of pump technology to deliver reliable and efficient solutions for a wide range of applications.The newly launched pumping solutions from Netzsch Pump are designed to address the growing demand for more advanced and versatile pumping systems in various industrial sectors such as chemical, food and beverage, oil and gas, and mining. These solutions are characterized by their high performance, reliability, and sustainability, making them ideal for critical and demanding industrial processes.Netzsch Pump's commitment to innovation and continuous improvement is evident in its new line of pumping solutions, which feature cutting-edge technologies such as progressive cavity pumps, rotary lobe pumps, and screw pumps. These technologies are engineered to optimize fluid handling, minimize energy consumption, and reduce maintenance requirements, thereby offering significant cost savings and operational efficiency for industrial operators.In addition to their advanced technological features, the new pumping solutions from Netzsch Pump are also designed with a focus on sustainability and environmental responsibility. By incorporating energy-efficient designs and utilizing eco-friendly materials, these solutions help industrial operators reduce their carbon footprint and contribute to a more sustainable future.Furthermore, Netzsch Pump's reputation for quality and reliability is reflected in its commitment to stringent quality control and testing standards. Each pumping solution undergoes rigorous testing to ensure its durability, performance, and safety, giving industrial operators the peace of mind that they are investing in a reliable and long-lasting pumping system.Netzsch Pump's dedication to customer satisfaction is another key aspect that sets the company apart in the industrial pumping market. The company offers comprehensive customer support services, including technical assistance, maintenance, and spare parts supply, to ensure that its customers have access to the resources they need to keep their pumping systems running optimally.With the introduction of its new line of pumping solutions, Netzsch Pump has once again demonstrated its position as a leading provider of innovative and reliable industrial pumping technologies. The company's commitment to excellence, sustainability, and customer satisfaction has positioned it as a trusted partner for industrial operators seeking cutting-edge pumping solutions.The global industrial market is constantly evolving, and the demand for advanced pumping solutions continues to grow. With its new line of innovative pumping solutions, Netzsch Pump is well-positioned to meet this demand and provide industrial operators with the high-performance and reliable pumping systems they need to thrive in today's competitive marketplace.In conclusion, the introduction of Netzsch Pump's new line of pumping solutions represents a significant milestone for the company and the industrial pumping industry as a whole. With its focus on innovation, sustainability, and customer satisfaction, Netzsch Pump continues to set the standard for excellence in industrial pumping technologies. As industrial operators seek more advanced and efficient pumping solutions, Netzsch Pump remains a trusted partner, delivering the reliable and high-performance pumping systems they need to succeed.

What Separates Centrifugal Pumps from Screw Pumps?

Centrifugal pumps and screw pumps are two common types of pumps used in various industrial applications. Although they both serve the purpose of moving fluids from one place to another, there are significant differences between the two in terms of their design, operation, and performance.A centrifugal pump uses a rotating impeller to create a suction force that draws fluid into the pump. The impeller then spins, forcing the fluid to the outer edges where it is then discharges through the pump's outlet. The velocity of the fluid is increased as it passes through the impeller, which increases the pressure of the fluid, allowing it to be moved more effectively through the system.On the other hand, a screw pump operates by using a rotating screw-shaped rotor to push the fluid through a stationary screw-shaped stator. The screws are designed to mesh together, and as they rotate, they create a series of sealed cavities that move the fluid through the pump and out through the discharge port. Unlike centrifugal pumps, the pressure generated by screw pumps is relatively constant, which makes them ideal for pumping high viscosity fluids, such as oil and sludge.While centrifugal pumps are suitable for a wide range of applications, including water treatment, chemical processing, and mining, screw pumps excel in moving fluids that are highly viscous and contain solids. They are often used in the oil and gas industry, marine transport, and other heavy-duty applications that require consistent, high-pressure flow.When choosing between a centrifugal pump and a screw pump, it's important to consider a variety of factors, such as the fluid being pumped, the flow rate needed, and the desired pressure. Additionally, the operational cost, maintenance requirements, and power consumption should also be taken into account.{} is a leading manufacturer of industrial pumps and fluid-handling equipment, with a comprehensive range of products designed to meet the needs of various industries worldwide. They provide a wide range of centrifugal and screw pumps, each designed to deliver optimal performance and reliability.For instance, the company's centrifugal pumps are engineered to provide high-efficiency pumping, low energy consumption, and long-term reliability, making them ideal for applications that require high flow rates and low-to-medium pressures. They are available in various designs, including end-suction, split-case, and vertical turbine pumps, to meet the specific requirements of different applications.Similarly, the company's screw pumps are designed to handle fluids with high viscosity, suspended solids, and abrasives, making them well-suited for industries such as wastewater treatment, chemical processing, and food and beverage. Their screw pumps come in various designs, including single-screw and twin-screw models, to accommodate different flow rates and pressure requirements.In addition to centrifugal and screw pumps, {} offers a wide range of other fluid-handling solutions, including mixers, agitators, valves, and filtration systems. They also provide related services, such as installation, commissioning, maintenance, and repair, to ensure that their customers' equipment always operates at peak performance.Overall, when it comes to choosing between a centrifugal pump and a screw pump, it ultimately comes down to the specific requirements of the application. {} offers a comprehensive range of pumps and fluid-handling solutions that are designed to meet the needs of different industries and applications, ensuring that their customers are able to find the perfect solution for their specific needs.

Highly Efficient Hsp Pump for Industrial Use

Hsp Pump, a leading player in the industrial pump industry, is revolutionizing the sector with its innovative products and solutions. The company has recently announced the launch of a new series of pumps that are set to redefine performance and efficiency standards in the industry.With a rich history spanning over three decades, Hsp Pump has established itself as a trusted provider of high-quality pumps for a wide range of applications. The company's commitment to excellence and innovation has made it a preferred choice for customers across various industries, including oil and gas, mining, water and wastewater, and chemical processing.The latest addition to Hsp Pump's product lineup is a result of extensive research and development efforts aimed at addressing the evolving needs of the industry. The new series of pumps boasts cutting-edge technology and advanced features that promise to deliver superior performance, reliability, and energy efficiency."Our team of engineers and technical experts have worked tirelessly to design and develop a pump series that not only meets but exceeds the expectations of our customers," said a spokesperson for Hsp Pump. "We understand the challenges faced by industries today, and our goal is to provide them with solutions that not only solve their pumping needs but also contribute to their overall operational efficiency and productivity."One of the key highlights of the new pump series is its advanced design, which incorporates state-of-the-art components and materials to ensure maximum durability and longevity. The pumps are engineered to withstand the harshest operating conditions, making them an ideal choice for demanding industrial applications.In addition to its robust construction, the new series of pumps also features an innovative hydraulic design that delivers exceptional performance and efficiency. With optimized impeller and volute geometries, the pumps are able to achieve higher flow rates and head capacities while consuming less power, resulting in significant energy savings for users.Furthermore, the pumps are equipped with intelligent monitoring and control systems that enable real-time performance tracking and remote operation. This not only allows for proactive maintenance and troubleshooting but also contributes to overall system reliability and uptime."We believe that the introduction of this new pump series will set a new standard in the industry," the spokesperson added. "Our customers can expect to experience unparalleled performance, reliability, and cost savings, making it a worthwhile investment for their operations."For customers looking to upgrade their existing pumping systems, Hsp Pump also offers comprehensive support and consulting services to ensure seamless integration and optimal performance. The company's team of experts is dedicated to providing tailored solutions that align with the specific needs and requirements of each customer.In line with its commitment to sustainability, Hsp Pump has also prioritized environmental considerations in the design and manufacturing of the new pump series. By focusing on energy-efficient and eco-friendly technologies, the company aims to help customers reduce their carbon footprint and contribute to a greener future.As Hsp Pump continues to drive innovation and excellence in the industrial pump industry, the launch of the new series of pumps solidifies its position as a forward-thinking and customer-centric solution provider. With a strong track record of delivering reliable and high-performance products, the company is poised to make a significant impact on the market and set new benchmarks for the industry as a whole.