Highly Efficient Rotating Pump for Improved Fluid Transfer

By:Admin

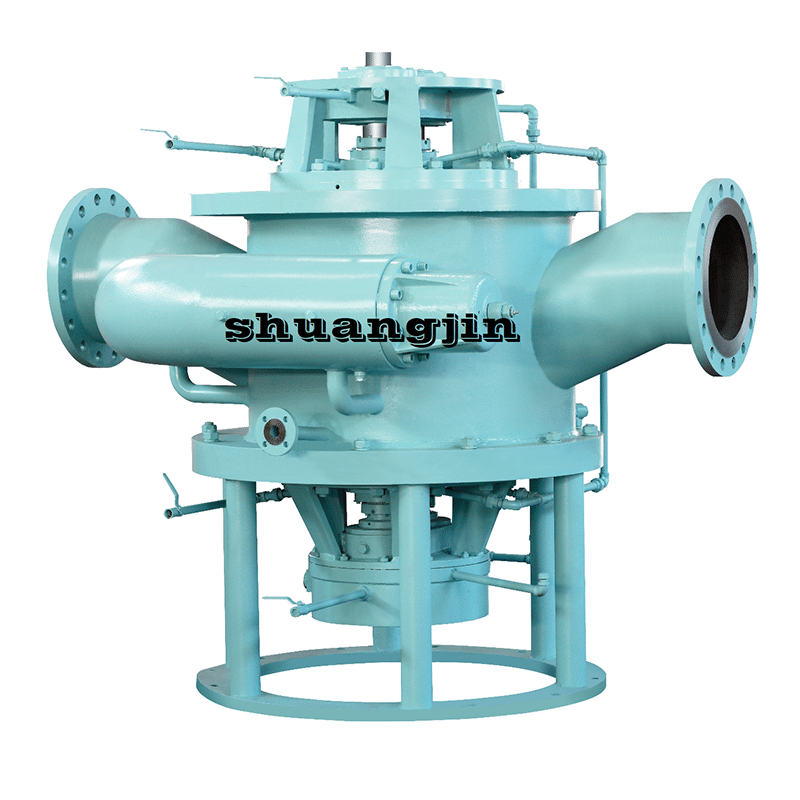

The company’s latest development, the new rotating pump, is set to redefine the standards for industrial pumps. This cutting-edge technology offers unparalleled performance and reliability, making it a game-changer in various industrial applications.

The rotating pump features a unique design that minimizes energy consumption while maximizing efficiency. Its advanced engineering ensures smooth and consistent operation, reducing downtime and maintenance costs for industrial facilities. Additionally, the pump’s robust construction and materials make it durable and capable of withstanding the demands of heavy-duty industrial environments.

One of the key advantages of the rotating pump is its versatility. It is suitable for a wide range of applications, including chemical processing, oil and gas, power generation, and water treatment. Its ability to handle varying viscosities and temperatures makes it an ideal solution for industrial processes that require precise fluid management.

In addition to its superior performance, the rotating pump also prioritizes safety and environmental responsibility. Its design incorporates features that help mitigate potential hazards and minimize the risk of leaks or spills. Furthermore, the pump is designed to comply with industry standards for environmental sustainability, ensuring that it aligns with the company’s commitment to responsible manufacturing.

The rotating pump represents Rotating Pump Solutions’ dedication to innovation and excellence. Since its inception, the company has continuously strived to push the boundaries of pump technology, aiming to provide customers with solutions that deliver unparalleled performance and value. This unwavering commitment has earned the company a reputation for delivering best-in-class products and services, making them a preferred partner for many industry professionals.

Furthermore, Rotating Pump Solutions places a strong emphasis on customer satisfaction. The company’s team of experts works closely with clients to understand their unique requirements and provide tailored solutions that address their specific needs. This customer-centric approach has earned the company a loyal customer base and has positioned them as a trusted advisor in the industry.

As the demand for efficient and reliable industrial pumps continues to grow, Rotating Pump Solutions remains at the forefront of innovation. The company’s investment in research and development and its dedication to continuous improvement ensure that their products consistently meet and exceed industry standards. The rotating pump is a testament to the company’s commitment to delivering cutting-edge solutions that empower their customers to achieve operational excellence.

Looking ahead, Rotating Pump Solutions is poised to further expand its presence in the global pump market. The company recognizes the importance of staying ahead of industry trends and evolving customer needs, and it is continuously investing in new technologies and capabilities to ensure its products remain at the forefront of innovation.

As industrial facilities seek to optimize their operations and maximize efficiency, the demand for advanced pumping solutions is only expected to grow. With its new rotating pump, Rotating Pump Solutions is well-prepared to meet this demand and help industrial customers achieve their operational goals.

In conclusion, Rotating Pump Solutions’ new rotating pump is a testament to the company’s commitment to innovation and excellence. Its superior performance, versatility, and focus on safety and environmental responsibility make it a standout solution in the industrial pump market. As the company continues to push the boundaries of pump technology, it is well-positioned to remain a leader in the industry and help its customers achieve sustained success.

Company News & Blog

Screw Pump vs Gear Pump: Understanding the Key Differences

Screw Pump And Gear Pump DifferenceAs a leading manufacturer in the fluid handling industry, [Company Name] has been producing high-quality pumps for a wide range of applications. With a focus on technology and innovation, the company has established itself as a reliable provider of pumping solutions for various industries. One of the key products in their lineup is the screw pump, which has gained popularity for its unique design and efficient performance. In this article, we will explore the differences between screw pumps and gear pumps, and how [Company Name] has become a trusted name in the pump manufacturing industry.Screw pumps and gear pumps are both types of positive displacement pumps, which means they are designed to move fluid by trapping a fixed amount of it and forcing it into the discharge pipe. However, there are some key differences between the two types of pumps that make them suitable for different applications.One of the main differences between screw pumps and gear pumps is their operating principle. Screw pumps utilize two intermeshing screws to move the fluid through the pump, while gear pumps use two gears to achieve the same result. This difference in design leads to some distinct advantages and disadvantages for each type of pump.Screw pumps are known for their ability to handle high-viscosity fluids with ease. The intermeshing screws create a continuous flow of fluid, allowing for smooth and efficient pumping of thick and viscous liquids. This makes screw pumps ideal for applications where high-pressure and high-viscosity fluids need to be handled, such as in the oil and gas industry.On the other hand, gear pumps are better suited for applications with lower viscosity fluids. The simple design of gear pumps makes them reliable and cost-effective for pumping low-viscosity fluids at moderate pressures. This makes gear pumps a popular choice for applications in industries such as chemical processing and food production.In addition to their different operating principles, screw pumps and gear pumps also differ in terms of their maintenance requirements. Screw pumps generally require less maintenance compared to gear pumps, due to their fewer moving parts and a more straightforward design. This can result in lower operating costs and reduced downtime for maintenance and repairs. On the other hand, gear pumps may require more frequent maintenance and replacement of parts, which can increase the overall cost of ownership.As a leading manufacturer in the pump industry, [Company Name] has extensive experience in designing and producing both screw pumps and gear pumps. Their engineering expertise and commitment to quality have made them a preferred supplier for companies looking for reliable pumping solutions. Their screw pumps are known for their robust construction and efficient performance, making them a popular choice for demanding applications in various industries.In addition to screw pumps, [Company Name] also offers a wide range of gear pumps, designed to meet the needs of customers requiring reliable and cost-effective pumping solutions for low-viscosity fluids. The company’s gear pumps are built to withstand the rigors of industrial applications, while providing consistent and reliable performance.In conclusion, screw pumps and gear pumps each have their unique advantages and are designed for specific applications. Companies like [Company Name] have leveraged their expertise to produce high-quality pumps that meet the diverse needs of their customers. With a strong focus on innovation and customer satisfaction, [Company Name] continues to be a trusted provider of pumping solutions for various industries around the world.

Screw Pump: Understanding its Function and Application in Various Industries

Pompa Screw Pump and Its Pioneering Technology in Industrial PumpingIn the world of industrial pumping, one name stands out - Pompa Screw Pump, a leading company in the design and manufacture of screw pumps for various industries. With their innovative technology and commitment to excellence, Pompa Screw Pump has established a strong reputation as a trusted partner for companies in need of reliable and high-performance pumping solutions.Pompa Screw Pump was founded in 1973 and has since become a global leader in the screw pump industry. The company's success can be attributed to its relentless pursuit of innovation and a deep understanding of the unique needs of their customers. With a team of highly skilled engineers and technicians, Pompa Screw Pump has been able to develop cutting-edge pumping technology that sets them apart from their competitors.One of the key factors that have contributed to Pompa Screw Pump's success is their unwavering commitment to quality. The company's products are manufactured to the highest standards and undergo rigorous testing to ensure their performance and durability. This dedication to quality has earned Pompa Screw Pump the trust and loyalty of their customers, who rely on their pumps for critical industrial processes.Pompa Screw Pump's product line encompasses a wide range of screw pumps that are designed to handle various applications, including oil and gas, petrochemical, marine, and power generation. Whether it's transporting crude oil, transferring chemicals, or boosting lubrication systems, Pompa Screw Pump's pumps are capable of delivering high flow rates and consistent performance, even in the most demanding operating conditions.But what sets Pompa Screw Pump apart from other pump manufacturers is their pioneering technology, particularly in the field of screw pump design. The company's engineers have developed innovative screw profiles and rotor geometries that maximize efficiency and minimize energy consumption. This means that Pompa Screw Pump's pumps not only deliver superior performance but also help their customers reduce their energy costs and environmental footprint.One of the standout products from Pompa Screw Pump is their X-Series screw pump, which features a unique rotor profile that ensures efficient and reliable operation. The X-Series pumps are designed to handle challenging applications, such as high-viscosity fluids and abrasive substances, making them an ideal choice for a wide range of industries.In addition to their cutting-edge technology, Pompa Screw Pump also places a strong emphasis on customer service and support. The company works closely with their clients to understand their specific pumping needs and provide customized solutions that meet their requirements. Pompa Screw Pump's team of experts offers comprehensive technical assistance, on-site support, and maintenance services to ensure that their customers' pumping systems operate at peak efficiency.Looking ahead, Pompa Screw Pump is poised to continue its leadership in the industrial pumping industry. The company is committed to ongoing research and development to further enhance their pumping technology and expand their product offerings. With a focus on innovation, quality, and customer satisfaction, Pompa Screw Pump is well-positioned to meet the evolving needs of the global market and remain a trusted partner for industrial pumping solutions.In conclusion, Pompa Screw Pump has set the bar high in the industrial pumping industry with its pioneering technology, unwavering commitment to quality, and dedication to customer service. As the company continues to grow and innovate, it is poised to remain a leading force in the world of screw pumps, providing reliable and efficient solutions for a wide range of industrial applications.

What Separates Centrifugal Pumps from Screw Pumps?

Centrifugal pumps and screw pumps are two common types of pumps used in various industrial applications. Although they both serve the purpose of moving fluids from one place to another, there are significant differences between the two in terms of their design, operation, and performance.A centrifugal pump uses a rotating impeller to create a suction force that draws fluid into the pump. The impeller then spins, forcing the fluid to the outer edges where it is then discharges through the pump's outlet. The velocity of the fluid is increased as it passes through the impeller, which increases the pressure of the fluid, allowing it to be moved more effectively through the system.On the other hand, a screw pump operates by using a rotating screw-shaped rotor to push the fluid through a stationary screw-shaped stator. The screws are designed to mesh together, and as they rotate, they create a series of sealed cavities that move the fluid through the pump and out through the discharge port. Unlike centrifugal pumps, the pressure generated by screw pumps is relatively constant, which makes them ideal for pumping high viscosity fluids, such as oil and sludge.While centrifugal pumps are suitable for a wide range of applications, including water treatment, chemical processing, and mining, screw pumps excel in moving fluids that are highly viscous and contain solids. They are often used in the oil and gas industry, marine transport, and other heavy-duty applications that require consistent, high-pressure flow.When choosing between a centrifugal pump and a screw pump, it's important to consider a variety of factors, such as the fluid being pumped, the flow rate needed, and the desired pressure. Additionally, the operational cost, maintenance requirements, and power consumption should also be taken into account.{} is a leading manufacturer of industrial pumps and fluid-handling equipment, with a comprehensive range of products designed to meet the needs of various industries worldwide. They provide a wide range of centrifugal and screw pumps, each designed to deliver optimal performance and reliability.For instance, the company's centrifugal pumps are engineered to provide high-efficiency pumping, low energy consumption, and long-term reliability, making them ideal for applications that require high flow rates and low-to-medium pressures. They are available in various designs, including end-suction, split-case, and vertical turbine pumps, to meet the specific requirements of different applications.Similarly, the company's screw pumps are designed to handle fluids with high viscosity, suspended solids, and abrasives, making them well-suited for industries such as wastewater treatment, chemical processing, and food and beverage. Their screw pumps come in various designs, including single-screw and twin-screw models, to accommodate different flow rates and pressure requirements.In addition to centrifugal and screw pumps, {} offers a wide range of other fluid-handling solutions, including mixers, agitators, valves, and filtration systems. They also provide related services, such as installation, commissioning, maintenance, and repair, to ensure that their customers' equipment always operates at peak performance.Overall, when it comes to choosing between a centrifugal pump and a screw pump, it ultimately comes down to the specific requirements of the application. {} offers a comprehensive range of pumps and fluid-handling solutions that are designed to meet the needs of different industries and applications, ensuring that their customers are able to find the perfect solution for their specific needs.

Best Tips for Efficient Heating and Cooling in Your Home

In today's rapidly changing world, the need for energy efficient solutions has become more important than ever. One company that has been at the forefront of this movement is {}. With a focus on innovative technology and a commitment to sustainability, {} has been leading the way in providing heating and cooling solutions that are not only efficient, but also environmentally friendly.As the demand for energy efficient heating and cooling systems continues to grow, {} has been at the forefront of developing cutting-edge solutions that meet the needs of both residential and commercial customers. With a wide range of products and services, {} has positioned itself as a leader in the industry, providing high-quality, reliable and cost-effective solutions that help customers reduce their energy consumption and lower their carbon footprint.At the heart of {}'s success is their dedication to innovation and technology. By constantly investing in research and development, {} has been able to stay ahead of the curve and deliver state-of-the-art products that are not only more efficient, but also more reliable and durable. Whether it's a new air conditioning unit for a home or a large-scale heating system for a commercial building, {} has the expertise and experience to deliver the right solution for any customer.In addition to their focus on innovation, {} is also committed to sustainability. By using environmentally friendly materials and manufacturing processes, {} is able to produce products that have a minimal impact on the environment. This commitment to sustainability has not only helped {} reduce its own carbon footprint, but has also enabled customers to make a positive environmental impact by choosing {}'s products and services.Another key aspect of {}'s success is their dedication to customer service. With a team of highly trained and experienced professionals, {} is able to provide the highest level of service and support to their customers. From initial consultation and product selection to installation and maintenance, {} is with their customers every step of the way, ensuring that they have a positive experience and that their heating and cooling systems are running at peak performance.Looking to the future, {} is poised to continue leading the way in heating and cooling solutions, with a focus on sustainable, energy efficient products and a commitment to customer satisfaction. By staying ahead of the curve and continually innovating, {} is well positioned to meet the evolving needs of the market and to continue providing high-quality solutions for many years to come.In conclusion, {} has established itself as a leader in the heating and cooling industry, with a strong focus on innovation, technology, sustainability, and customer service. As the demand for energy efficient solutions continues to grow, {} is well positioned to continue providing cutting-edge products and services that meet the needs of residential and commercial customers alike.

Highly efficient multiphase pumps revolutionize oil and gas industry

Multiphase Pumps, a leading provider of innovative pumping solutions, has been making waves in the oil and gas industry with its cutting-edge technology and superior performance. With a commitment to excellence and a dedication to meeting the needs of their clients, Multiphase Pumps has established itself as a trusted partner in the energy sector.Founded in 2002, Multiphase Pumps has quickly risen to prominence as a global leader in multiphase pumping systems. The company's state-of-the-art technology allows for the efficient and reliable transportation of oil, gas, and water in a variety of challenging environments. Their pumps are designed to handle the complexities of multiphase flow, making them an ideal solution for offshore and subsea applications.Multiphase Pumps has a strong track record of delivering high-performance pumping solutions to the oil and gas industry. Their team of experienced engineers and technicians work tirelessly to develop innovative and reliable products that meet the evolving needs of their clients. With a focus on continuous improvement and technological advancement, Multiphase Pumps is at the forefront of pump technology and is continuously striving to exceed industry standards.One of the key factors that set Multiphase Pumps apart from its competitors is their commitment to customer satisfaction. The company prides itself on its ability to provide tailored pumping solutions that meet the specific needs of each client. Whether it's a complex subsea project or a high-pressure onshore operation, Multiphase Pumps has the expertise and experience to deliver reliable and efficient solutions.In addition to their commitment to excellence, Multiphase Pumps is also dedicated to sustainability and environmental responsibility. The company's pumps are designed to minimize emissions and energy consumption, making them an environmentally friendly choice for energy companies around the world. By prioritizing sustainability, Multiphase Pumps is contributing to the global effort to reduce the carbon footprint of the oil and gas industry.Multiphase Pumps' dedication to innovation, quality, and customer satisfaction has earned them a solid reputation in the oil and gas industry. Their pumps are known for their reliability, efficiency, and durability, making them a top choice for energy companies seeking high-performance pumping solutions. With a focus on continuous improvement and a commitment to meeting the unique needs of their clients, Multiphase Pumps is well positioned to continue leading the way in multiphase pumping technology.In recent news, Multiphase Pumps has announced the successful launch of a new generation of multiphase pumping systems. The latest addition to their product lineup features advanced technology that enhances efficiency and reliability, while also reducing environmental impact. The new pumps have been designed to meet the demands of the evolving energy industry, providing a solution that is both cost-effective and sustainable."We are thrilled to introduce our latest generation of multiphase pumping systems to the market," said the CEO of Multiphase Pumps. "Our team has worked tirelessly to develop a product that not only meets the performance expectations of our clients but also aligns with our commitment to environmental responsibility. We are confident that these new pumps will set a new standard for multiphase pumping technology."The new generation of pumps from Multiphase Pumps represents a significant leap forward in pump technology. With enhanced performance capabilities and a focus on sustainability, these pumps are poised to revolutionize the way oil and gas companies transport multiphase fluids. By offering a reliable and efficient solution that also supports environmental goals, Multiphase Pumps is setting a new benchmark for the industry.As Multiphase Pumps continues to push the boundaries of pump technology, the company remains dedicated to delivering innovative and sustainable solutions to its clients. With a proven track record of excellence and a commitment to meeting the unique needs of the energy industry, Multiphase Pumps is well positioned to maintain its leadership position in the market. Through a combination of cutting-edge technology, a focus on customer satisfaction, and a dedication to sustainability, Multiphase Pumps is poised for continued success in the years to come.

Understanding the Role of Lube Oil Pumps in Engine Functionality

Title: Lube Oil Pump Function: Enhancing Efficiency and Reliability in Industrial MachineryIntroduction:With the increasing demand for industrial machinery's performance and longevity, the role of reliable components becomes crucial. Among them, the lube oil pump stands out as an integral part of the lubrication system, ensuring smooth operation and extended lifespan of various large-scale machineries. This article focuses on the fascinating functionalities and benefits of lube oil pumps while highlighting their significance in enhancing efficiency and reliability in industrial machinery.Functionality of Lube Oil Pump:A lube oil pump plays a pivotal role in machinery lubrication systems, primarily designed to provide a consistent and regulated flow of oil to various crucial components. Its prime function is to ensure proper lubrication in order to minimize friction, heat, wear and tear, and enhance operational efficiency.1. Oil Circulation Mechanism:A lube oil pump utilizes an intricate mechanism to circulate oil throughout the machinery. The pump, driven by an electric motor or the equipment's engine, draws oil from the sump or oil reservoir, propelling it through a series of pipes and channels to the targeted components.2. Pressure Regulation:To cater to the specific lubrication requirements of different machinery components, lube oil pumps possess the ability to regulate the oil pressure. This feature ensures that the oil reaches every nook and cranny of the machinery, reducing the chances of components running dry and potential damages caused by friction.3. Filtration:One of the essential functions of a lube oil pump is to ensure clean oil reaches the machinery's components. The pumps are equipped with built-in filtration systems that remove contaminants like dirt, debris, and metal particles that may have accumulated in the oil. This mechanism protects the machinery's critical elements, extending their lifespan and reducing maintenance requirements.4. Cooling Mechanism:Industrial machinery often generates substantial heat during operation. Lube oil pumps aid in preventing overheating by circulating cooled oil to areas prone to high temperatures. This assists in dissipating heat and maintaining optimal operating conditions, reducing the risk of equipment failure.Significance in Enhancing Efficiency and Reliability:The functionality of a lube oil pump is directly linked to enhancing efficiency and reliability in industrial machinery. By providing proper lubrication, these pumps have numerous benefits that contribute to the smooth functioning and extended lifespan of the equipment.1. Friction Reduction:Efficient lubrication from a lube oil pump helps minimize friction between moving components. This reduction in friction reduces energy loss, allowing machinery to operate more efficiently and potentially saving energy costs for businesses.2. Wear and Tear Reduction:By keeping machinery components well-lubricated, lube oil pumps effectively reduce wear and tear. This, in turn, minimizes the chances of breakdowns, extends the machinery's lifespan, and reduces the need for frequent repairs or replacements.3. Increased Productivity:Lube oil pumps ensure that machinery is always in optimal condition to perform at its best. By reducing friction, wear and tear, and potential heat-related failures, these pumps contribute to uninterrupted production schedules, resulting in increased productivity and profitability.4. Minimized Downtime:Extended machinery lifespan, coupled with reduced maintenance requirements due to well-lubricated components, translates to minimized downtime for businesses. This leads to increased operational efficiency and cost savings attributed to decreased repair and maintenance expenses.Conclusion:In today's industrial landscape, where machinery performance and longevity are crucial, lube oil pumps play an indispensable role. Their functionality, including efficient oil circulation, pressure regulation, filtration, and cooling mechanisms, significantly enhances the efficiency and reliability of industrial machinery. These pumps minimize friction, reduce wear and tear, increase productivity, and minimize downtime for businesses, making them an essential component to ensure sustainable operations and financial success in the industrial sector.

New Gas Pump Technology Promises More Fuel Efficiency and Faster Refueling

CTP Pump, leading supplier of industrial pumps and equipment, has announced an expansion of their product line to meet the growing demand for innovative and efficient pumping solutions in the manufacturing and processing industries.With a focus on providing high-quality and reliable products, CTP Pump has been a trusted supplier to a wide range of industries for over 30 years. The company offers a comprehensive range of pumping solutions, including centrifugal pumps, diaphragm pumps, and gear pumps, as well as a variety of accessories and components to meet the specific needs of their customers.In response to the increasing demand for advanced pumping technology, CTP Pump has introduced a new line of innovative and efficient pumps that are designed to improve performance, reduce energy consumption, and lower operating costs. These new products have been developed in collaboration with leading industry experts and are backed by extensive research and development to ensure they meet the highest standards of quality and reliability.The new product line includes a range of high-efficiency centrifugal pumps that are designed to deliver superior performance and energy savings. These pumps are equipped with state-of-the-art technology, such as advanced impeller designs and precision-engineered components, to provide optimal flow rates and pressure levels while minimizing maintenance requirements and downtime.In addition to centrifugal pumps, CTP Pump has also expanded their portfolio to include a new series of diaphragm pumps that are specifically designed to handle a wide range of fluids, including corrosive and abrasive materials. These pumps feature a rugged and durable construction, as well as innovative diaphragm designs that ensure reliable and consistent performance in the most demanding applications.Furthermore, CTP Pump has introduced a new line of gear pumps that are engineered for efficient and reliable operation in a variety of industrial and commercial settings. These pumps are designed to deliver precise and consistent flow rates, as well as high levels of durability and longevity to meet the needs of their customers.As a leading supplier of industrial pumps and equipment, CTP Pump is committed to providing comprehensive solutions to help their customers improve their operational efficiency and productivity. The company's team of experienced engineers and technicians are available to support their customers throughout every step of the pump selection, installation, and maintenance process.In addition to their extensive product line, CTP Pump offers a variety of services, including technical support, maintenance and repair, and customized pumping solutions to meet the specific needs of their customers.With the introduction of their new product line, CTP Pump is poised to further strengthen their position as a trusted provider of innovative and efficient pumping solutions for the manufacturing and processing industries. The company's commitment to quality, reliability, and customer satisfaction makes them the preferred choice for businesses looking to enhance their pumping operations.For more information about CTP Pump and their range of industrial pumping solutions, visit their website or contact their sales team to discuss specific requirements and learn more about the benefits of their new product line.

High-Quality Water Pump for Gear Machinery: A Comprehensive Guide

Gear Water Pump, one of the leading companies in the field of water pump technology, has recently announced the launch of their latest innovation in water pump systems. The new technology is set to revolutionize the way water is pumped and distributed, offering a more efficient and reliable solution for a range of applications.With over 20 years of experience in the industry, Gear Water Pump has established itself as a trusted name in the field of water pump manufacturing. The company is known for its commitment to innovation and quality, and the latest product release is a testament to their dedication to providing cutting-edge solutions for their customers.The new water pump technology from Gear Water Pump is designed to deliver superior performance and reliability, making it an ideal choice for a wide range of applications including agricultural irrigation, industrial water supply, and municipal water distribution. The innovative design of the pump ensures efficient water flow and minimal energy consumption, making it an environmentally friendly and cost-effective solution for water pumping needs.One of the key features of the new water pump technology is its advanced gear system, which delivers a smooth and consistent water flow, reducing the risk of pump failure and maintenance downtime. This makes the pump ideal for applications where continuous water supply is essential, such as in agricultural irrigation and industrial processes.In addition to its superior performance, the new water pump technology from Gear Water Pump is also designed with durability in mind. The pump is built to withstand harsh operating conditions and is constructed from high-quality materials to ensure long-term reliability and performance. This makes it an ideal choice for demanding applications where reliable water supply is crucial.Furthermore, Gear Water Pump has also integrated smart technology into their new water pump system, allowing for remote monitoring and control of the pump performance. This feature enables users to track the pump's operating status and performance in real-time, making it easier to identify and address any potential issues before they escalate. This remote monitoring capability is especially valuable for large-scale water pumping operations where keeping the system running smoothly is a top priority.The launch of the new water pump technology from Gear Water Pump has garnered significant attention in the industry, with experts praising the company for its commitment to innovation and quality. The company's dedication to developing cutting-edge water pump solutions has cemented its position as a leader in the field, and the latest product release is expected to further solidify its reputation in the market.With the demand for efficient and reliable water pump solutions on the rise, Gear Water Pump's new technology is set to make a significant impact in the industry. The company's long-standing reputation for excellence, combined with the advanced features of the new water pump system, positions Gear Water Pump as a top choice for customers seeking a dependable and high-performance water pumping solution.As Gear Water Pump continues to push the boundaries of water pump technology, the industry can expect to see even more innovative and groundbreaking solutions from the company in the future. With a strong focus on quality, performance, and durability, Gear Water Pump is poised to remain a driving force in the water pump industry for years to come.

High-performance Multiphase Pump for Efficient Fluid Handling

Multiphase Pump Technology Revolutionizes Oil and Gas ProductionIn the fast-paced and ever-evolving world of oil and gas production, the need for efficient and effective multiphase pumping technology has never been greater. The demands of increased production from unconventional resources, the challenges of offshore and subsea operations, and the need for more cost-effective and environmentally friendly solutions have all combined to drive the development of innovative multiphase pumping solutions.One company at the forefront of this technological revolution is {}. With a strong commitment to research and development, practical engineering, and customer focus, {} has become a leader in multiphase pump technology and has been instrumental in driving the adoption of multiphase pumping systems in the oil and gas industry.{}’s multiphase pump systems are designed to handle a wide range of fluid mixtures, including gas, oil, and water, in a single pipeline. This revolutionary technology eliminates the need for separate gas and liquid handling equipment, significantly reducing capital and operating costs for oil and gas producers. In addition, {}’s multiphase pumping systems are capable of delivering increased production rates, improved efficiency, and enhanced flexibility for a variety of applications, including onshore and offshore fields, subsea developments, and heavy oil and oil sands production.The technology behind {}’s multiphase pump systems is based on a combination of advanced engineering, cutting-edge materials, and innovative design. By leveraging the latest advancements in computational fluid dynamics, finite element analysis, and additive manufacturing, {}’s engineers have been able to optimize the performance and reliability of their multiphase pumping solutions. In addition, {}’s multiphase pump systems are built to withstand the harsh operating conditions of the oil and gas industry, including high pressures, extreme temperatures, and corrosive environments, ensuring long-term performance and durability.{}’s commitment to customer focus is evident in the company’s comprehensive approach to multiphase pump technology. {}’s team of experts works closely with oil and gas producers to understand their specific challenges and requirements, providing tailored solutions to maximize efficiency and productivity. Furthermore, {} offers a full range of services, including installation, commissioning, training, and ongoing support, to ensure that their customers are able to fully leverage the benefits of multiphase pumping technology.The impact of {}’s multiphase pump technology on the oil and gas industry has been significant. By enabling oil and gas producers to increase production rates, optimize reservoir recovery, and reduce capital and operating costs, {}’s multiphase pump systems have become essential tools for maximizing the value of oil and gas assets. In addition, the environmentally friendly nature of multiphase pumping, which reduces emissions and minimizes the need for separate gas handling facilities, is in line with the industry's increasing focus on sustainability and responsible resource development.Looking ahead, {} is committed to continuing the development of multiphase pump technology, with ongoing investments in research and development, engineering innovation, and customer support. With the demand for multiphase pumping solutions expected to grow as oil and gas producers seek to maximize the potential of unconventional resources and improve operational efficiency, {} is well-positioned to play a key role in the future of the oil and gas industry.In conclusion, {}’s multiphase pump technology has revolutionized oil and gas production by providing cost-effective, efficient, and environmentally friendly solutions for handling complex fluid mixtures. With a focus on research and development, practical engineering, and customer support, {} has become a leader in multiphase pump technology and is poised to continue driving innovation and value for the oil and gas industry.

Common Disadvantages of Screw Pumps You Should Know

Screw Pump Disadvantages Screw pumps have been widely used in various industries for their ability to handle a wide range of fluids, including high-viscosity liquids, and for their efficiency in delivering a constant flow. However, despite their numerous advantages, screw pumps also come with their own set of disadvantages that can impact their performance and efficiency.One of the main disadvantages of screw pumps is their susceptibility to abrasive wear. The rotating screws and the pump casing are subject to continuous contact with the pumped fluid, which can contain abrasive particles. Over time, this can lead to wear and erosion of the pump components, ultimately reducing the pump's efficiency and lifespan. Another drawback of screw pumps is their sensitivity to changes in fluid viscosity. While screw pumps are known for their ability to handle high-viscosity fluids, they can struggle to maintain a consistent flow when the viscosity of the pumped fluid varies. This can result in fluctuations in the pump's performance and the quality of the output, making it less reliable in certain applications.Additionally, the design of screw pumps makes them more prone to clogging compared to other types of pumps. The tight clearances between the rotating screws and the pump casing can lead to the accumulation of debris and solids, which can obstruct the flow of the pumped fluid and cause operational issues. This can be a significant drawback in industries where the pumped fluids may contain a high concentration of solids or impurities.Furthermore, screw pumps are known for their relatively high maintenance requirements. The intricate design of the pump and the close tolerances between the rotating components necessitate regular maintenance and repairs to ensure optimal performance. This can result in higher operating costs and downtime, particularly in industrial settings where continuous operation is crucial.Despite these disadvantages, several companies, including {} continue to use screw pumps in their operations. Founded in 1999, {} has established itself as a leading provider of pumping solutions for a wide range of industries, including oil and gas, marine, and industrial applications. The company's extensive product line includes a variety of pump types, including screw pumps, centrifugal pumps, and diaphragm pumps, among others.{}'s screw pumps are renowned for their robust construction, high efficiency, and reliable performance, making them a popular choice for handling challenging fluids in demanding environments. The company's dedication to innovation and quality has allowed it to develop state-of-the-art screw pumps that address many of the traditional disadvantages associated with this pump type.For instance, {}'s screw pumps are equipped with advanced materials and coatings that enhance their resistance to abrasive wear, extending their lifespan and reducing maintenance requirements. The company's engineering team has also implemented innovative design features to mitigate the effects of fluid viscosity variations, ensuring consistent and reliable performance across a wide range of operating conditions.In addition, {}'s screw pumps are designed with larger clearances and anti-clogging features to minimize the risk of debris accumulation and blockages, making them well-suited for handling fluids with high solids content. This has made {}'s screw pumps a preferred choice for industries where the pumping of abrasive or viscous fluids is a common requirement.Moreover, {} offers comprehensive aftermarket support and a global network of service centers to provide timely maintenance and repair services for its screw pumps, minimizing downtime and maximizing the reliability of its pumping solutions. With a commitment to customer satisfaction and a focus on continuous improvement, {} has positioned itself as a trusted partner for companies seeking reliable and efficient pumping solutions.In conclusion, while screw pumps have their own set of disadvantages, companies like {} are continuously innovating and improving the design and performance of these pumps to overcome these challenges. By addressing issues such as abrasive wear, fluid viscosity sensitivity, clogging, and maintenance requirements, {} has demonstrated the potential for screw pumps to remain a valuable and reliable pumping solution for a wide range of industries.