High-Quality Pumps Make Waves in the Industry

By:Admin

One of the key factors that sets Inoxpa Pumps apart from its competitors is its commitment to research and development. The company has a dedicated team of engineers and technical experts who are constantly working to improve and innovate their products. This focus on innovation has led to the development of a number of cutting-edge pumping solutions that offer higher efficiency, greater reliability, and lower operating costs.

Inoxpa Pumps offers a comprehensive range of pumping solutions to suit a variety of applications. The company's product line includes centrifugal pumps, positive displacement pumps, and rotary lobe pumps, among others. These pumps are designed to handle a wide range of fluids, from thin, non-viscous liquids to highly viscous and abrasive substances. Inoxpa Pumps also offers a range of accessories and spare parts, ensuring that customers have everything they need to keep their pumping systems running smoothly.

Inoxpa Pumps has a strong focus on quality and reliability, and all of its products are manufactured to the highest standards. The company's state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, allowing them to produce pumps that are not only efficient and reliable but also durable and long-lasting. Inoxpa Pumps also has a rigorous quality control process in place, ensuring that every pump that leaves their facilities meets their strict standards for performance and reliability.

One of the key strengths of Inoxpa Pumps is its customer service and support. The company has a global network of sales and service partners, ensuring that customers all over the world have access to the support and assistance they need. Inoxpa Pumps also offers a range of after-sales services, including maintenance and repair, as well as technical support and training. This commitment to customer support has helped the company build a strong reputation for reliability and dependability.

Inoxpa Pumps is also committed to sustainability and environmental responsibility. The company is constantly striving to reduce its environmental impact and has implemented a number of initiatives to promote sustainability throughout its operations. This includes the use of energy-efficient manufacturing processes, the development of eco-friendly products, and the implementation of waste reduction and recycling programs.

Inoxpa Pumps has established itself as a trusted and reliable provider of pumping solutions for a wide range of industries, and its innovative products and commitment to quality and customer service have set it apart as a leader in the industry. With its focus on research and development, quality manufacturing, and sustainability, Inoxpa Pumps is well-positioned to continue its success in the years to come.

Company News & Blog

Discover the Benefits of Efficient Electric Heating Pumps in Home Heating Systems

Title: Innovative Electric Heating Pump Revolutionizes Energy EfficiencyIntroduction:In today's world, where energy conservation and sustainable practices are crucial, one company is spearheading a remarkable advancement in heating technology. {Company Name}, a leading innovator in the field, has recently unveiled their groundbreaking Electric Heating Pump, poised to revolutionize energy efficiency.The Electric Heating Pump:Designed to provide both heating and cooling solutions for residential and commercial buildings, the Electric Heating Pump breaks new ground with its advanced functionality and eco-friendly design. By utilizing cutting-edge technology, this pump offers a highly efficient and cost-effective alternative to traditional heating systems.Operating Principle:The Electric Heating Pump employs a heat transfer process that extracts heat energy from the ambient air, enabling it to provide heating during colder months. It works on the same principle as a refrigerator, but in reverse. By absorbing heat from the surrounding environment, it elevates the temperature and releases warm air into the building, ensuring a comfortable living or working space.Key Features:1. Energy Efficiency: The Electric Heating Pump significantly reduces energy consumption by utilizing the heat present in the air, making it up to three times more energy-efficient than conventional heating methods. It helps users achieve substantial savings on their energy bills while protecting the environment.2. Versatility: Apart from providing efficient heating, the Electric Heating Pump also doubles as an air conditioner during warmer months. This versatile feature ensures year-round comfort, regardless of the season.3. Smart Technology Integration: Equipped with smart controls, the Electric Heating Pump allows users to effortlessly customize temperature settings according to their preferences. This user-friendly interface ensures optimized efficiency and convenience.4. Silent Operation: Designed with noise reduction features, the Electric Heating Pump operates silently, eliminating the annoyance of loud fans or compressors typically associated with traditional heating systems.Addressing Climate Change:As the world grapples with the increasingly pressing issue of climate change, technologies like the Electric Heating Pump play a pivotal role in transitioning to sustainable practices. By reducing greenhouse gas emissions and relying on the freely available heat energy in the environment, the pump aligns with global efforts to combat climate change.Company Name's Commitment:{Company Name} is at the forefront of driving sustainable solutions, developing pioneering products that contribute to energy conservation and environmental protection. With over {number} years of expertise in the industry, the company combines innovative engineering and a commitment to customer satisfaction to deliver state-of-the-art technology.Market Impact:The introduction of the Electric Heating Pump is set to disrupt the heating industry by setting new standards in energy efficiency. By offering an alternative to traditional heating systems, this advanced technology ensures reduced carbon footprints while delivering significant savings to consumers.Conclusion:In a world that demands energy-efficient and sustainable solutions, the Electric Heating Pump offers a game-changing heating and cooling solution. {Company Name's} commitment to developing innovative technologies not only enhances consumer comfort but also contributes to a greener, more sustainable future. With the Electric Heating Pump, efficiency, convenience, and environmental consciousness merge, setting a new benchmark in the industry.

Discover the Benefits of High-Quality Pumps for RSP Requirements

Breaking News: Revolutionary Fuel Pump Technology Set to Transform the Automotive IndustryIn a groundbreaking turn of events, a new and innovative fuel pump technology is poised to revolutionize the way we fuel our vehicles. The highly anticipated Rsp Pump, developed by an industry-leading company, is set to transform the automotive landscape with its cutting-edge advancements. The Rsp Pump, short for Revolutionary Series Pump, is the brainchild of a team of dedicated engineers and scientists who share a common vision of developing sustainable and efficient fueling solutions for the future. With its unique features and state-of-the-art design, the Rsp Pump promises to deliver unparalleled performance, safety, and environmental benefits.One of the key features of the Rsp Pump is its enhanced fuel efficiency. By employing advanced fuel injection techniques and optimizing the combustion process, this revolutionary fuel pump technology ensures that each drop of fuel is utilized to its maximum potential. This not only translates into significant cost savings for vehicle owners but also reduces carbon emissions, contributing to a cleaner and greener environment.Moreover, the Rsp Pump boasts a user-friendly interface, making it accessible to all drivers, regardless of their technical expertise. Equipped with a smart display system, the pump provides real-time information on fuel consumption, engine health, and diagnostic alerts. This data empowers drivers to make informed decisions about their driving habits and optimize their fuel usage.Safety is also a top priority for the Rsp Pump. The pump is equipped with advanced sensors and automated safety mechanisms to prevent accidents or fuel spills during the refueling process. This ensures that both the vehicle and the environment remain protected at all times. Furthermore, the Rsp Pump incorporates an anti-tampering mechanism, preventing any unauthorized access or modifications to the pump, guaranteeing fuel integrity and security.Beyond its technical capabilities, the Rsp Pump also contributes to the overall sustainability goals of the automotive industry. The pump's manufacturing process prioritizes eco-friendly materials and energy-efficient production methods. Moreover, the Rsp Pump continuously undergoes rigorous testing and improvement to minimize its environmental impact throughout its lifecycle.As part of its commitment to promoting a sustainable future, the developer of the Rsp Pump has collaborated with various stakeholders in the automotive industry to support the adoption of this groundbreaking technology. Through strategic partnerships with renowned car manufacturers, fuel providers, and regulatory bodies, the Rsp Pump is set to become an integral part of the global automotive ecosystem.Industry experts have lauded the Rsp Pump as a game-changer for the automotive industry, with its potential to influence not only the way we fuel our vehicles but also the broader shift towards cleaner and more sustainable transportation. With its numerous advantages, the Rsp Pump is expected to gain widespread acceptance and become a standard feature in vehicles of the future.In conclusion, the Rsp Pump is poised to bring about a paradigm shift in the automotive industry. With its exceptional fuel efficiency, advanced safety features, and commitment to sustainability, this revolutionary fuel pump technology sets a new benchmark for the sector as a whole. As the world embraces greener alternatives, the Rsp Pump paves the way for a future where sustainability and performance harmoniously coexist.

Introduction to Different Types of Industrial Valves - A Comprehensive Guide

Industrial Valves: A Leader in Innovation and Reliability[date]Industrial Valves, a global leader in valve manufacturing, continues to set the standards in the industry with its innovative and reliable products. With a rich history dating back several decades, the company has built a strong reputation for its commitment to quality, customer satisfaction, and technological advancements.Headquartered in [location], Industrial Valves has a vast network of manufacturing facilities and offices across the globe, allowing them to cater to the diverse needs of their worldwide clientele. The company's extensive product range includes a wide variety of valves, such as gate valves, globe valves, ball valves, butterfly valves, and control valves. Their valves are utilized in various industries, including oil and gas, petrochemical, power generation, water treatment, and many more.One of the key factors that sets Industrial Valves apart from its competitors is its relentless focus on innovation. The company invests heavily in research and development to constantly improve their products and stay at the forefront of technological advancements. By utilizing state-of-the-art manufacturing processes and cutting-edge materials, Industrial Valves ensures that their valves are not only durable and reliable but also meet the ever-evolving needs of the industry.Industrial Valves takes pride in their commitment to quality. The company has implemented a strict quality management system, adhering to international standards and certifications. Each valve undergoes rigorous testing and inspection to ensure it meets or exceeds industry regulations. With a zero-tolerance approach towards defects, Industrial Valves guarantees that their valves are of the highest quality, providing peace of mind to their customers.In addition to their focus on innovation and quality, Industrial Valves places utmost importance on customer satisfaction. The company's team of highly skilled engineers and technicians work closely with clients to understand their unique requirements and offer tailored solutions. From initial design and engineering to installation and after-sales support, Industrial Valves provides comprehensive services to ensure customer satisfaction throughout the entire lifecycle of their valves.With a strong commitment to sustainability, Industrial Valves also develops eco-friendly solutions. The company invests in research and development of valves that minimize environmental impact, reduce energy consumption, and increase operational efficiency. By offering sustainable solutions, Industrial Valves contributes to the overall well-being of the planet while helping their clients achieve their environmental goals.Industrial Valves' dedication to excellence has earned them numerous accolades and industry recognition. They have been awarded multiple contracts for high-profile projects globally, solidifying their position as a trusted and reliable valve manufacturer. Their valves have consistently proven their worth in challenging environments and demanding applications, demonstrating their ability to perform under extreme conditions.Looking towards the future, Industrial Valves remains committed to pushing the boundaries of innovation and meeting the evolving needs of the industry. With ongoing investments in research and development and a focus on customer satisfaction, the company is well-positioned to continue its growth trajectory and maintain its reputation as a global leader in the valve manufacturing sector.In conclusion, Industrial Valves is a company that exemplifies excellence in valve manufacturing. With their commitment to innovation, quality, and customer satisfaction, they have established themselves as a trusted partner for industries across the globe. Continuously pushing boundaries and embracing technological advancements, Industrial Valves sets the bar high for others in the industry, solidifying their position as a leader in innovation and reliability.

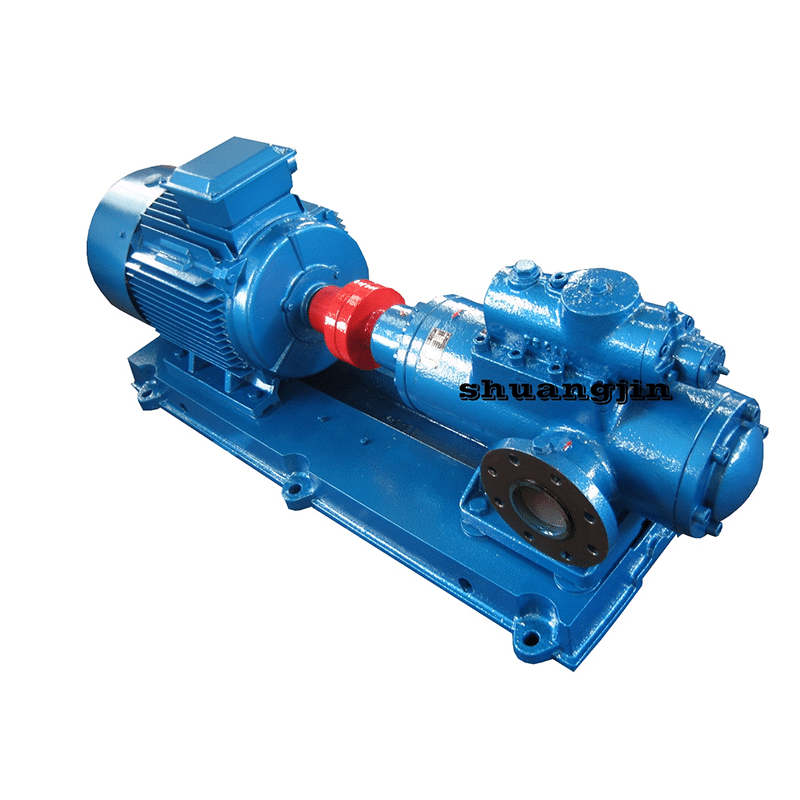

Top Sanitary Twin Screw Pumps for Industrial Use

Sanitary Twin Screw Pumps are a crucial component for many industries, including food and beverage, pharmaceuticals, and personal care products. These pumps are designed to handle delicate materials, such as viscous liquids, shear-sensitive products, and abrasive slurries, with high efficiency and precision.One company at the forefront of manufacturing and distributing these state-of-the-art pumps is {Company Name}. With a strong focus on innovation and customer satisfaction, {Company Name} has quickly become a leading provider of sanitary twin screw pumps for a wide range of applications.The unique design of {Company Name}'s sanitary twin screw pumps allows for gentle product handling, making them ideal for transferring sensitive materials without compromising their integrity. The pumps are also designed for easy disassembly and cleaning, ensuring compliance with strict sanitation and hygiene regulations in the industries they serve.In addition to their advanced design, {Company Name}'s sanitary twin screw pumps are known for their reliability and long-term performance. With a commitment to quality and durability, these pumps are built to withstand the rigors of continuous operation, reducing maintenance needs and downtime for their customers.{Company Name} offers a comprehensive range of sanitary twin screw pumps to meet the diverse needs of their clients. Whether it's for transferring highly viscous food products, delicate pharmaceutical ingredients, or abrasive personal care formulations, {Company Name} has a solution to suit every requirement. Their pumps are available in various sizes and configurations, allowing for customization to fit specific application needs.Furthermore, {Company Name} takes pride in providing exceptional customer service and technical support. Their team of experts is dedicated to assisting clients in selecting the right pump for their unique needs and providing ongoing support to ensure optimal performance and efficiency. With a strong emphasis on building lasting relationships with their customers, {Company Name} is known for their reliability and commitment to excellence.One of the key factors that sets {Company Name} apart in the industry is their continuous innovation and investment in research and development. By staying at the forefront of technological advancements, {Company Name} consistently improves and refines their products, offering cutting-edge solutions that exceed industry standards.{Company Name}'s commitment to sustainability is also evident in their operations. They strive to minimize their environmental impact through energy-efficient manufacturing processes and the use of eco-friendly materials whenever possible. This dedication to sustainability aligns with the values of many of their clients, making {Company Name} a preferred supplier for those with a focus on responsible business practices.In conclusion, {Company Name} is a leading provider of sanitary twin screw pumps, offering high-quality, reliable, and innovative solutions for a wide range of industries. With a focus on customer satisfaction, technical expertise, and sustainable practices, {Company Name} has established itself as a trusted partner in the field of fluid handling equipment. Whether it's for gentle product handling, precision transfer, or long-term performance, {Company Name} has the expertise and products to meet the most demanding requirements.

The Significance of Timing Gears in Screw Pumps: Exploring their Role and Function

Timing Gear in Screw Pump: A Revolutionary Advancement in Pump Technology[Company Name], a leading innovator in the field of pump technology, has recently unveiled a breakthrough development in screw pump design – the revolutionary Timing Gear. This state-of-the-art advancement is set to transform the way pumps function, offering enhanced efficiency, reliability, and durability.Traditional screw pump designs rely on a rotating helical screw to move fluids through the pump. While these pumps have proven to be effective for many applications, they often suffer from issues such as uneven fluid flow, excessive vibration, and premature wear of the screw and other internal components.With the introduction of the Timing Gear, [Company Name] aims to eliminate these drawbacks and create a new benchmark in screw pump performance. This innovative gear mechanism, which replaces the traditional single-helix screw, provides precise control over the flow of fluids, resulting in smoother operation and improved overall efficiency.One of the primary advantages of the Timing Gear is its ability to maintain a consistent flow rate, regardless of variations in input pressure or viscosity of the fluid being pumped. This feature makes it highly suitable for applications where a reliable and steady flow is crucial, such as in the oil and gas industry, chemical processing plants, and wastewater treatment facilities.Additionally, the Timing Gear significantly reduces unwanted vibrations that can cause excessive wear and tear on pump components. By incorporating advanced engineering principles, including precision machining and advanced materials, [Company Name] has ensured that their Timing Gear pumps operate with minimal noise and vibrations, thereby increasing their service life and reducing maintenance costs.Another noteworthy feature of the Timing Gear is its remarkable durability. The gear mechanism is designed to withstand high operating pressures and resist corrosion, making it suitable for use in harsh and demanding environments. Its robust construction ensures long-term reliability and reduced downtime, providing businesses with a cost-effective solution for their pumping needs.Furthermore, the Timing Gear’s design allows for easy maintenance and quick replacement of worn components. Its modular construction enables users to access and replace specific parts, reducing the need for extensive disassembly and minimizing downtime during servicing. Additionally, the gear’s simplicity of design enhances reliability, as fewer moving parts mean fewer opportunities for mechanical failures.[Company Name] has already received overwhelmingly positive feedback from early adopters of the Timing Gear. Companies that have integrated this groundbreaking technology into their pump systems have reported significant improvements in efficiency, productivity, and overall performance. Several industry experts have also praised this innovation, recognizing its potential to revolutionize the screw pump market.In conclusion, [Company Name]’s introduction of the Timing Gear has set a new standard in screw pump technology. With its precise flow control, reduced vibrations, exceptional durability, and ease of maintenance, this groundbreaking development promises to deliver a range of benefits to businesses across various sectors. As this revolutionary advancement gains traction in the industry, it is expected to redefine the capabilities and expectations of screw pumps, establishing [Company Name] as a leader in pump technology innovation.

Versatile Commercial Gear Pump: A Powerful Industrial Solution for Multiple Applications

Commercial Gear Pump Keeps the World in MotionCommercial Gear Pump is a leading manufacturer of high-quality gear pumps, delivering reliable and efficient pumping solutions for various industries worldwide. Established in 1915, the company's impressive history spans over a century of continuous innovation, growth, and success.The company prides itself on its dedication to engineering excellence, customer satisfaction, and environmental responsibility. Its gear pumps feature precision-made parts, strict quality control, and state-of-the-art testing to ensure consistent performance and durability for even the most demanding applications.Commercial Gear Pump's products include external and internal gear pumps, vane pumps, and accessories such as relief valves, strainers, and flow meters. They are available in a wide range of sizes, materials, and configurations to meet various fluid handling needs, from low-viscosity oils and fuels to high-viscosity adhesives and polymers.One of the company's flagship products is the CG-024 external gear pump, which combines superior design, materials, and assembly for maximum efficiency, reliability, and ease of maintenance. The pump's robust construction features a cast iron body, heat-treated gears, and high-strength shafts for long-lasting performance even in harsh environments.The CG-024 pump also incorporates advanced sealing technology that minimizes leakage and reduces energy consumption, leading to significant cost savings and reduced environmental impact. Additionally, it can be customized with various options such as multiple ports, adjustable relief valves, and special coatings to suit specific applications.Moreover, Commercial Gear Pump's expertise extends beyond traditional gear pump design and manufacturing. The company can also provide custom solutions that combine pumps with other components such as motors, drives, control systems, and sensors, to create integrated systems that maximize efficiency, accuracy, and safety.Commercial Gear Pump's excellent products and services have gained it a reputation as a trusted partner for many industries such as oil and gas, chemical processing, food and beverage, medical equipment, and transportation. Its customers benefit not only from top-quality gear pumps but also from the company's technical support, training, and aftermarket services that ensure optimal performance throughout the lifespan of the equipment.Recently, Commercial Gear Pump has made significant progress in expanding its global presence and market share. The company has opened new sales offices and service centers in strategic locations such as the Middle East, Asia, and Europe. It has also strengthened its distribution network and partnerships with leading OEMs and distributors worldwide.One of the factors driving Commercial Gear Pump's success is its commitment to research and development. The company invests heavily in innovation and technology to continuously improve its products and processes, and to explore new opportunities for growth and diversification.For example, Commercial Gear Pump is developing new pump models that incorporate smart features such as remote monitoring, predictive maintenance, and energy optimization. These solutions aim to enhance the efficiency, reliability, and safety of fluid handling systems, which are critical components of many industrial processes and infrastructures.Furthermore, the company is exploring new applications for its gear pumps, such as renewable energy, biotech, and water treatment, where its expertise in pumping challenging fluids and materials can make a significant difference in achieving sustainable and cost-effective solutions.In conclusion, Commercial Gear Pump is a company that truly embodies the spirit of innovation, quality, and customer focus. Its gear pumps are essential components of many critical industrial processes worldwide, and its commitment to excellence has earned it a well-deserved reputation as a leader in the fluid handling industry.Through continuous improvements, expansion, and diversification, Commercial Gear Pump is poised to continue its growth and success while contributing to the advancement of various industries and the well-being of society.

10 Essential Applications of Screw Pumps in Various Industries

The Use of Screw Pump: Understanding the Importance in Industrial ApplicationsScrew pumps have been around for a while and used in industrial applications for various reasons. They have become popular because of their efficiency and versatility, with many companies using it for different purposes. These pumps can be found in oil and gas industries, food-processing plants, petrochemical plants, and many more.Screw pumps work by moving fluid inside their chambers. A helical screw rotates inside a cylinder, creating pressure that forces fluid to flow through the pump. As it moves, it also moves pockets of fluid along the way, which reduces pulsation, ensures smooth continuous flow, and maximizes efficiency.Thanks to screw pumps, manufacturers can efficiently move liquids without disturbing the medium's temperature, density, or viscosity. It's perfect for transferring both low and high viscosity liquids, making it the perfect solution for moving anything from crude oil to food products.This pump is versatile, cost-effective, and often replaceable. However, like any machinery, there are advantages and disadvantages to using a screw pump. Below, we'll take a look at some of the benefits of using screw pumps in your system.Advantages of Screw Pumps1. Low Maintenance RequirementsOne of the primary advantages of using a screw pump is that it requires minimal maintenance. The low maintenance requirements of screw pumps make it cost-effective, and you will save a considerable amount of money in maintenance and repairs.2. Efficient PerformanceScrew pumps are designed for maximum efficiency. They can handle high and low viscosity liquids, making it easy to move anything from crude oil to food products. Their design optimizes the flow of liquid, reducing pulsations and ensuring smooth, continuous flow.3. High Suction CapabilityScrew pumps can handle high suction, making it easy to transfer liquids of different viscosities. They can handle everything from light fuel oils to heavy crude oil.4. Can Handle Multiple ViscositiesScrew pumps are suitable for transferring liquids of different viscosities. They are often used in the oil and gas industry, where they can be used to transfer crude oil, diesel fuel, and heavy oil.5. They Are VersatileScrew pumps are highly versatile. They are used in a variety of industries for many different purposes, making them ideal for any application that requires the movement of liquids.6. Reduced Noise LevelScrew pumps are relatively quiet, making them ideal for indoor settings where noise levels need to be kept to a minimum.How to Select the Right Screw PumpSelecting the right screw pump is essential to ensure that you get the desired results. The best way to select the right screw pump is to work with a reputable and experienced manufacturer. When selecting a screw pump, you need to consider factors such as:1. The Viscosity of the LiquidThe viscosity of the liquid you are transferring is a crucial factor when selecting a screw pump. You need to ensure that the pump you choose can handle the viscosity of the liquid.2. Temperature of the LiquidConsider the temperature of the liquid you will be transferring. Screw pumps are suitable for liquid temperatures of up to 350 degrees Celsius.3. Characteristics of the LiquidConsider the characteristics of the liquid you will be transferring. The physical characteristics of the liquid will impact the type of screw pump you choose.ConclusionScrew pumps are essential for many industries. They are versatile, efficient, and cost-effective, making them the perfect solution for moving liquids of various viscosities. When selecting a screw pump, it's essential to choose an experienced and reputable manufacturer to ensure that you get the desired results.

How to Maintain Your Pump's Lube Oil System for Optimum Performance

Lube Oil System for Pumps Improves Operational Efficiency With the global demand for energy constantly on the rise, the oil and gas industry has been working towards improving operational efficiency and reducing costs. One critical area that has been identified is the upkeep and maintenance of industrial pumps, which play a vital role in the production and distribution of various types of fuels. To address this issue, a leading provider of pump systems and solutions has launched a new lube oil system that promises to revolutionize the way pumps are maintained and serviced.The lube oil system, developed by [company name], is designed to offer a complete solution for the lubrication and cooling of industrial pumps. It provides a reliable and consistent supply of oil to critical pump components, ensuring their proper functioning and longevity. The system features a compact design that makes it easy to install and maintain, with minimal downtime and disruption to operations.One of the key benefits of the lube oil system is its ability to provide accurate and real-time monitoring of pump performance. The system is equipped with sensors that measure oil pressure, temperature, and flow rate, allowing operators to detect any issues or abnormalities in pump operation. This proactive approach to maintenance can help prevent costly downtime and repairs, while also optimizing the performance and longevity of the pump.In addition to its monitoring capabilities, the lube oil system is also designed for easy maintenance and service. The system's modular design allows for easy access to critical components, making it simple to replace parts or perform routine maintenance tasks. This, in turn, reduces the need for specialized technical expertise and training, further reducing costs and improving efficiency.The lube oil system is compatible with a wide range of industrial pumps, including centrifugal, positive displacement, and reciprocating pumps. It can be customized to meet the specific needs of different pump applications, including offshore drilling, refining, and transportation. This versatility means that the system can be used across a wide range of industries, making it a valuable investment for any company looking to improve pump performance and reduce maintenance costs.Commenting on the launch of the new lube oil system, [company name]'s CEO said, "We are proud to introduce this innovative solution to the market. Our team has worked tirelessly to develop a lube oil system that delivers real value to our customers. We believe that this system will help our customers achieve better operational efficiency, reduce maintenance costs, and minimize downtime. Ultimately, our goal is to help our customers succeed, and we believe that this system will play a key role in achieving that."Overall, the lube oil system for pumps offered by [company name] is a game-changer for the oil and gas industry. Its ability to provide real-time monitoring, easy maintenance, and compatibility with various pump types makes it an ideal solution for companies looking to optimize pump performance and reduce maintenance costs. With this system, operators can focus on their core business operations, while relying on the lube oil system to keep their pumps running smoothly and efficiently.

Introducing Advanced Screw Pumps for Enhanced Performance

The Oil and Gas industry is a vital sector that plays a significant role in powering our world. With frequent technological advancements and increased demand for sustainability, the industry constantly seeks to improve its operations and processes. One technology that has benefited the industry over the years is the use of Screw Pumps.Screw pumps are positive displacement pumps that work by using two or more helical rotors or screws to move fluids through the pump. These pumps are ideal for handling viscous liquids, abrasive fluids, and liquids containing entrained gases. Among the top manufacturers of screw pumps is Leistritz, a global company that has been in operation for over 100 years.Leistritz is known for its innovative and high-quality screw pumps that serve a variety of industries, including oil and gas, marine, chemical, and pharmaceuticals. The company is dedicated to providing its customers with reliable products that meet their specific requirements. Leistritz Screw Pumps are engineered to optimize different applications, from low viscosity to high viscosity fluids.One of the unique features of Leistritz Screw Pumps is their ability to handle a wide range of fluids effectively. These pumps are designed to handle aggressive chemicals, high-temperature liquids, and fluids with a high solid content. They are also used in various applications, such as crude oil transfer, refrigeration, lubrication, and fuel supply.Leistritz Screw Pumps come in different configurations to meet the needs of different applications. For instance, the company's L3NG series is designed for low viscosity fluids, while the L4 series is ideal for high viscosity fluids. These pumps use various materials, including bronze, stainless steel, and carbon steel, to suit different applications.One exciting feature of Leistritz Screw Pumps is their efficiency and reliability. These pumps have a high volumetric flow rate and can deliver fluid without pulsation. They are designed with fewer components, reducing the chances of mechanical failure and downtime. Additionally, Leistritz Screw Pumps require minimal maintenance, making them a cost-effective solution for the end-users.In the oil and gas sector, Leistritz Screw Pumps are widely used in various areas, from upstream operations to downstream refineries. For instance, in upstream operations, these pumps are used in crude oil transfer, drilling mud circulation, and water injection. Their efficiency and reliability make them an essential component in the production process.In midstream operations, Leistritz Screw Pumps are used in pipelines to transport crude oil and other fluids over long distances. These pumps offer high flow rates and can handle fluids with a high solids content, making them ideal for pipeline applications. By using screw pumps, midstream operators can transport fluids effectively over long distances, reducing the need for additional pumping stations.In downstream operations, Leistritz Screw Pumps are used in refineries for various applications, such as lubrication, fuel supply, and asphalt transfer. These pumps can handle high-temperature liquids and aggressive chemicals, making them ideal for the corrosive environment of a refinery.In conclusion, Leistritz Screw Pumps are a reliable and efficient solution for various applications in the oil and gas industry. Their ability to handle viscous and abrasive fluids, as well as liquids with entrained gases, makes them a versatile tool in the industry. With over a century of experience, Leistritz has established itself as a leading manufacturer of screw pumps, providing innovative solutions to its customers.

The Importance of Proper Oil Pump Lubrication for Efficient Operations

[Company Name] Revolutionizes Oil Pump Lubrication with Cutting-Edge Technology[City], [Date] - [Company Name], a leading innovator in industrial lubrication systems, has recently unveiled a groundbreaking solution that is set to transform oil pump lubrication. The company's new technology aims to enhance efficiency, reduce maintenance costs, and extend equipment lifespan, revolutionizing the lubrication industry.Oil pump lubrication plays a vital role in various industries such as oil and gas, automotive, and manufacturing. Traditionally, this process has relied on manual lubrication, which is not only time-consuming but also prone to human error. [Company Name] recognized the need for an advanced automated lubrication system that could streamline the process while ensuring optimal performance and reliability.The newly developed solution offers a range of benefits over traditional manual lubrication methods. Firstly, it eliminates the need for manual intervention, as the system is designed to automatically monitor and supply the precise amount of lubricant required for optimal pump performance. This not only saves time but also ensures consistent lubrication, reducing the risk of equipment damage caused by improper lubrication.Moreover, the technology incorporates intelligent sensors and advanced algorithms that continuously monitor the condition of the lubricant and the pump itself. By analyzing key parameters such as temperature, pressure, and vibration, the system can detect potential faults or anomalies in real-time. This proactive approach allows for timely maintenance and repair, minimizing downtime and extending the lifespan of the equipment.Furthermore, [Company Name]'s new lubrication system is compatible with a wide range of pumps, offering versatility for various applications. Whether it is a centrifugal, reciprocating, or gear pump, the system can be seamlessly integrated, optimizing lubrication efficiency across industries.To ensure the successful implementation of their lubrication system, [Company Name] offers comprehensive training programs and ongoing technical support. Their team of highly skilled engineers are available to assist with installation, calibration, and troubleshooting, ensuring a smooth transition and maximizing the benefits of the new technology.In addition to the technical advantages, [Company Name] is committed to environmental sustainability. The automated lubrication system is designed to minimize lubricant waste by applying the right amount of lubricant precisely where it is needed. By reducing lubricant consumption and minimizing leakages, the system not only helps organizations reduce costs but also contribute to a greener, more sustainable future."Oil pump lubrication is a critical process in industries worldwide, and our aim was to develop a solution that simplifies and optimizes this essential task," said [Spokesperson's Name], the spokesperson for [Company Name]. "Our innovative system not only enhances efficiency but also ensures the longevity and reliability of the equipment, saving time and resources for our customers."The groundbreaking technology developed by [Company Name] is set to revolutionize the oil pump lubrication industry. By combining automation, intelligent monitoring, and compatibility with various pump types, the company has created a solution that offers significant advantages over traditional manual lubrication methods. With its commitment to customer support and environmental sustainability, [Company Name] is poised to become the leader in the lubrication industry.