High Performance Three Screw Pump Series Unveiled in Latest News

By:Admin

The SN Series Three Screw Pump is a game-changing addition to [Company Name]'s extensive range of pumping solutions. Leveraging the latest in pump technology and engineering expertise, this pump is designed to deliver exceptional performance, reliability, and efficiency across a wide range of applications. Whether it's for industrial processes, oil and gas, marine, or other critical applications, the SN Series Three Screw Pump is engineered to meet the most demanding requirements with ease.

One of the key highlights of the SN Series Three Screw Pump is its advanced three-screw design, which enables smooth and pulsation-free flow, resulting in improved efficiency and reduced noise levels. This innovative design also allows for a wide range of viscosities and temperatures, making it a versatile and adaptable solution for various pumping needs. Additionally, the pump is built to withstand high pressures and abrasive media, ensuring long-term durability and performance in the most challenging operating conditions.

Furthermore, the SN Series Three Screw Pump is equipped with state-of-the-art sealing technology, which enhances its reliability and minimizes the risk of leaks and downtime. This, coupled with its robust construction and easy maintenance, makes it a cost-effective and low-maintenance solution for businesses looking to optimize their operations and minimize total cost of ownership.

As a company with a long-standing reputation for excellence in pump manufacturing, [Company Name] is committed to delivering high-quality and innovative solutions that address the evolving needs of its customers. With the introduction of the SN Series Three Screw Pump, the company aims to set a new benchmark for performance, reliability, and efficiency in the pumping industry and ensure its customers have access to cutting-edge solutions that drive operational excellence and productivity.

In addition to its technical capabilities, [Company Name] also boasts a strong commitment to customer support, ensuring that its clients receive the necessary guidance and assistance to select, install, and maintain the SN Series Three Screw Pump for optimal performance and longevity. The company's team of experienced engineers and customer service professionals are readily available to provide technical expertise, troubleshoot issues, and offer tailored solutions to meet specific application requirements.

Moreover, [Company Name] is known for its global presence, with a network of distributors and service centers spanning across different regions. This ensures that customers around the world have access to the SN Series Three Screw Pump and can benefit from the company's renowned expertise and support, no matter where they are located.

In conclusion, the introduction of the SN Series Three Screw Pump marks a significant milestone for [Company Name] and the pumping industry as a whole. With its advanced design, exceptional performance, and unwavering commitment to customer satisfaction, this innovative pump is poised to make a lasting impact on a wide range of industries, driving efficiency, reliability, and productivity for its users. As the demand for high-performance pumping solutions continues to grow, [Company Name] is well-positioned to lead the way with its cutting-edge products and unwavering dedication to excellence.

Company News & Blog

Newly Designed Oil Pump Machine Offered at Competitive Prices

The oil pump machine is an essential piece of equipment in the oil and gas industry, used for extracting and transporting crude oil from the ground to refineries. These machines are crucial for ensuring the smooth and efficient operation of oil wells, and they play a vital role in meeting the world's ever-growing demand for energy. One company that has been leading the way in the development and production of oil pump machines is {}. With a strong focus on innovation and quality, the company has established itself as a trusted supplier of oil pump machines to the global oil and gas industry. The company's cutting-edge technology and commitment to excellence have made its products highly sought after by oil companies around the world.{} has a long history of designing and manufacturing high-performance oil pump machines that are built to withstand the demanding conditions of the oil field. The company's machines are known for their reliability, efficiency, and durability, making them the top choice for oil producers looking to maximize their productivity and minimize downtime.One of the key features of {}'s oil pump machines is their advanced control systems, which allow for precise monitoring and adjustment of the pump's operation. This level of control not only maximizes the machine's efficiency but also helps to prevent costly downtime and maintenance issues. Additionally, {}'s oil pump machines are designed with a focus on safety, incorporating features that help to mitigate the risks associated with oil extraction and transportation.In addition to its high-quality products, {} also prides itself on its exceptional customer service. The company's team of experts is dedicated to providing comprehensive support to its clients, offering technical assistance, maintenance services, and training programs to ensure that its oil pump machines continue to perform at their best.{}'s commitment to excellence extends beyond its products and services - the company is also dedicated to sustainability and environmental responsibility. The company continuously explores new technologies and processes to minimize the environmental impact of its operations, and it actively promotes energy efficiency and conservation within the oil and gas industry.The market for oil pump machines is expected to experience significant growth in the coming years, driven by the increasing global demand for energy and the ongoing development of new oil fields. As a leading supplier of oil pump machines, {} is well-positioned to capitalize on these opportunities and continue to expand its presence in the global market.In conclusion, {}. The company's dedication to innovation, quality, and customer satisfaction has made it a trusted partner for oil producers around the world. With a strong focus on sustainability and environmental responsibility, {} is well-prepared to meet the evolving needs of the oil and gas industry and continue to drive innovation in oil pump technology.

Top Check Valve for Well Pump: A Comprehensive Guide

Check Valve For Well Pump Ensures Reliable and Efficient Water Flow{company name} is proud to announce the release of their high-quality check valve for well pumps, designed to enhance the performance and longevity of well water systems. With over [number] years of experience in manufacturing pump components, {company name} has built a reputation for delivering reliable and innovative solutions to meet the needs of the water industry. The new check valve is the latest addition to their product line, offering superior functionality and durability for well pump systems.The check valve plays a crucial role in maintaining the integrity of well water systems by preventing backflow and ensuring a consistent flow of water. {company name}'s check valve is designed with precision engineering and premium materials to provide reliable protection against water hammer, backflow, and other potential issues that can occur in well pump systems.One of the key features of {company name}'s check valve is its durable construction. Made from high-quality materials, the check valve is built to withstand the harsh conditions often found in well water systems. Its robust design ensures long-term performance and minimal maintenance, reducing the risk of downtime and costly repairs for well owners.In addition to its durability, the check valve is also designed for easy installation and compatibility with a wide range of well pump systems. {company name} understands the importance of convenience for their customers and has engineered the check valve to be user-friendly and versatile, allowing for seamless integration into existing well pump setups.Furthermore, the check valve is engineered for efficient water flow, helping to optimize the performance of well pump systems. By reducing the risk of backflow and water hammer, the check valve contributes to smoother water flow and more consistent water pressure, enhancing the overall efficiency of well water systems.{company name} prides itself on its commitment to product excellence and customer satisfaction. As part of their dedication to quality, the check valve for well pumps has undergone rigorous testing and quality control measures to ensure that it meets the highest standards for performance and reliability. Customers can have confidence in {company name}'s products, knowing that they are backed by extensive research, development, and testing processes.The release of the check valve for well pumps reflects {company name}'s ongoing commitment to innovation and technological advancement in the water industry. By continuously investing in research and development, {company name} strives to stay at the forefront of the market, offering cutting-edge solutions that address the evolving needs of well owners and water system operators.In addition to the check valve, {company name} offers a comprehensive range of pump components and accessories, catering to a diverse array of applications within the water industry. With a focus on quality, reliability, and performance, {company name} has established itself as a trusted provider of pump solutions, earning the trust and loyalty of customers worldwide.As the demand for efficient and reliable well pump systems continues to grow, {company name} remains at the forefront of delivering innovative solutions that empower well owners to maintain and optimize their water systems. The release of the check valve for well pumps underscores {company name}'s dedication to providing essential components that contribute to the long-term sustainability and performance of well water systems.For more information about {company name}'s check valve for well pumps or to explore their comprehensive range of pump components and accessories, please visit their official website or contact their customer service team. With a commitment to excellence and a passion for innovation, {company name} is poised to continue driving advancements in the water industry, supporting the needs of well owners and water system operators globally.

Ultimate Guide to Three-Screw Pumps: Everything You Need to Know

Title: Innovative Three-Screw Pump Enhances Industrial ProcessesIntroduction (78 words):In an exciting development for industries reliant on efficient fluid transfer systems, a leading manufacturer has introduced a new generation three-screw pump. This cutting-edge technology, boasting high efficiency, exceptional reliability, and advanced features, is poised to revolutionize fluid transfer operations across sectors such as oil and gas, chemical processing, and power generation. By providing superior performance and reducing maintenance needs, this pump will undoubtedly be a game-changer in enhancing industrial processes worldwide.Paragraph 1 (117 words):The revolutionary 3G Series Three-Screw Pump, developed by a reputable company, is driven by a steadfast commitment to delivering innovative solutions. Designed to meet the escalating demands of diverse industries, this next-generation pump promises unmatched performance and uncompromising reliability. Engineered with precision, it exhibits superior properties such as low noise levels, reduced pulsations, and increased efficiency, ensuring optimal fluid transfer throughout critical processes. Additionally, the incorporation of advanced sealing technology enhances leak prevention, minimizing downtime and maximizing operational productivity. By combining these cutting-edge features, the 3G Series Three-Screw Pump sets a new standard for performance, further solidifying its position as a leader in industrial fluid transfer systems.Paragraph 2 (135 words):With fluid transfer operations being a vital component in industries such as oil and gas, chemical processing, and power generation, the demand for efficient and reliable pumps has never been higher. The 3G Series Three-Screw Pump addresses this need through its innovative design and outstanding performance capabilities. This pump's adaptability allows it to transfer a wide range of fluids, including high-viscosity liquids, abrasive media, and corrosive substances, all while maintaining consistent and reliable outcomes. Moreover, the sophisticated construction of the pump ensures longevity and resilience, even under the harshest operating conditions. As a result, industries can significantly reduce downtime, maintenance costs, and losses associated with compromised fluid transfer systems.Paragraph 3 (149 words):In addition to its robust performance, the 3G Series Three-Screw Pump also showcases an environmentally conscious design. By minimizing energy consumption and reducing waste, this pump contributes to a sustainable future. Its state-of-the-art construction and advanced engineering techniques enable high energy efficiency, resulting in cost savings and reduced carbon emissions. With a focus on sustainability, this pump is ideal for companies looking to align their operations with global environmental initiatives.To further enhance the customer experience, the manufacturer offers comprehensive technical support and maintenance services. Their team of experts provides timely assistance, ensuring smooth installation, operation, and troubleshooting. This commitment to customer satisfaction highlights the dedication of the company, cementing its reputation as a trusted partner in industrial fluid transfer solutions.Conclusion (91 words):In conclusion, the introduction of the 3G Series Three-Screw Pump marks a significant milestone in fluid transfer technology. With its exceptional performance, reliability, and environmentally friendly design, this pump offers a superior solution to meet the evolving needs of industries worldwide. By reducing downtime, maintenance costs, and environmental impact, this innovative pump opens new opportunities for enhancing industrial processes. As companies seek to streamline operations and improve sustainability, the 3G Series Three-Screw Pump emerges as the ideal choice, revolutionizing fluid transfer systems for a more efficient and environmentally conscious future.

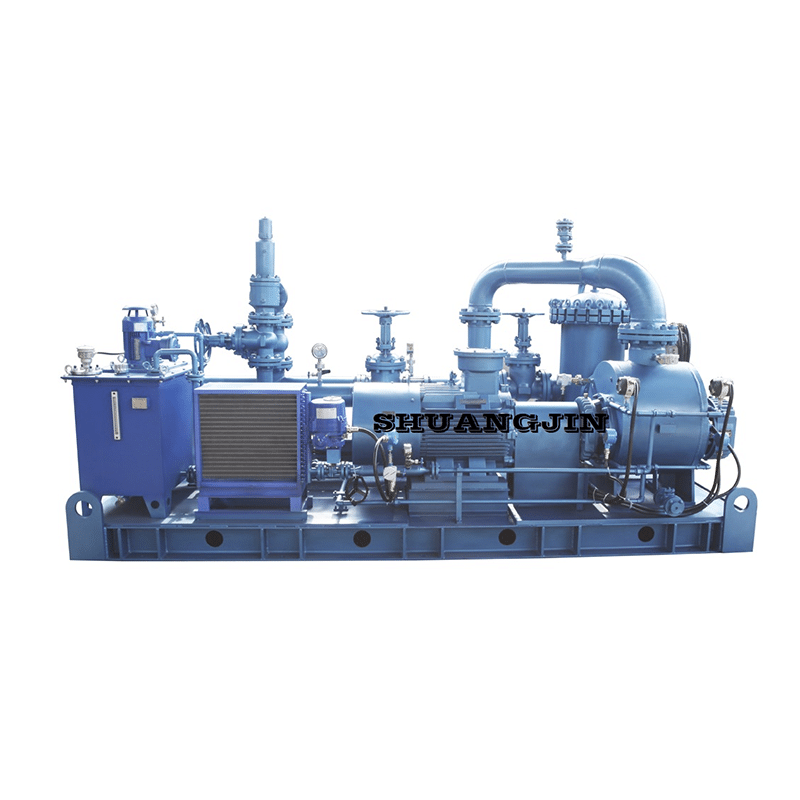

High-Quality Pump Products from China: A Closer Look at Shuangjin Pump

China Shuangjin Pump Products, a leading manufacturer of industrial pumps, has been making strides in the global market with its high-quality products and innovative solutions. The company has established itself as a trusted name in the pump industry, and its dedication to excellence and customer satisfaction has earned it a loyal customer base.With over 30 years of experience, China Shuangjin Pump Products has continuously invested in research and development to keep up with the latest technologies and industry trends. This has enabled the company to stay ahead of the competition and deliver cutting-edge pump solutions to its customers. From centrifugal pumps to submersible pumps, China Shuangjin Pump Products offers a wide range of products that cater to various industries, including water treatment, mining, and agriculture.One of the key factors that set China Shuangjin Pump Products apart from its competitors is its commitment to quality. The company adheres to strict quality control measures throughout the manufacturing process to ensure that its pumps meet the highest standards. In addition, China Shuangjin Pump Products has obtained various certifications and accreditations, further affirming its dedication to delivering reliable and durable products to its customers.Furthermore, China Shuangjin Pump Products also places a strong emphasis on innovation. The company has a team of experienced engineers and designers who are constantly working on improving existing products and developing new solutions to meet the evolving needs of the market. This focus on innovation has allowed China Shuangjin Pump Products to stay relevant and competitive in an ever-changing industry landscape.In addition to its impressive product range and commitment to quality, China Shuangjin Pump Products also prides itself on its customer-centric approach. The company works closely with its clients to understand their specific requirements and provide tailored pump solutions that best suit their needs. This personalized approach has earned China Shuangjin Pump Products a reputation for reliability and customer satisfaction.Moreover, China Shuangjin Pump Products has also been expanding its presence in the global market. The company has established a strong distribution network that spans across various countries, allowing it to reach customers worldwide. This global expansion has enabled China Shuangjin Pump Products to further strengthen its position as a leading supplier of industrial pumps on the international stage.Looking ahead, China Shuangjin Pump Products is poised to continue its growth and success in the industry. The company remains dedicated to driving innovation, delivering quality products, and providing exceptional customer service. With its unwavering commitment to excellence, China Shuangjin Pump Products is well-positioned to maintain its status as a trusted leader in the pump manufacturing sector.In conclusion, China Shuangjin Pump Products has established itself as a prominent player in the industrial pump industry, thanks to its unwavering commitment to quality, innovation, and customer satisfaction. With a diverse product range, a customer-centric approach, and a global presence, China Shuangjin Pump Products is well-equipped to meet the evolving needs of the market and continue its success in the years to come.

Introduction to Different Types of Industrial Valves - A Comprehensive Guide

Industrial Valves: A Leader in Innovation and Reliability[date]Industrial Valves, a global leader in valve manufacturing, continues to set the standards in the industry with its innovative and reliable products. With a rich history dating back several decades, the company has built a strong reputation for its commitment to quality, customer satisfaction, and technological advancements.Headquartered in [location], Industrial Valves has a vast network of manufacturing facilities and offices across the globe, allowing them to cater to the diverse needs of their worldwide clientele. The company's extensive product range includes a wide variety of valves, such as gate valves, globe valves, ball valves, butterfly valves, and control valves. Their valves are utilized in various industries, including oil and gas, petrochemical, power generation, water treatment, and many more.One of the key factors that sets Industrial Valves apart from its competitors is its relentless focus on innovation. The company invests heavily in research and development to constantly improve their products and stay at the forefront of technological advancements. By utilizing state-of-the-art manufacturing processes and cutting-edge materials, Industrial Valves ensures that their valves are not only durable and reliable but also meet the ever-evolving needs of the industry.Industrial Valves takes pride in their commitment to quality. The company has implemented a strict quality management system, adhering to international standards and certifications. Each valve undergoes rigorous testing and inspection to ensure it meets or exceeds industry regulations. With a zero-tolerance approach towards defects, Industrial Valves guarantees that their valves are of the highest quality, providing peace of mind to their customers.In addition to their focus on innovation and quality, Industrial Valves places utmost importance on customer satisfaction. The company's team of highly skilled engineers and technicians work closely with clients to understand their unique requirements and offer tailored solutions. From initial design and engineering to installation and after-sales support, Industrial Valves provides comprehensive services to ensure customer satisfaction throughout the entire lifecycle of their valves.With a strong commitment to sustainability, Industrial Valves also develops eco-friendly solutions. The company invests in research and development of valves that minimize environmental impact, reduce energy consumption, and increase operational efficiency. By offering sustainable solutions, Industrial Valves contributes to the overall well-being of the planet while helping their clients achieve their environmental goals.Industrial Valves' dedication to excellence has earned them numerous accolades and industry recognition. They have been awarded multiple contracts for high-profile projects globally, solidifying their position as a trusted and reliable valve manufacturer. Their valves have consistently proven their worth in challenging environments and demanding applications, demonstrating their ability to perform under extreme conditions.Looking towards the future, Industrial Valves remains committed to pushing the boundaries of innovation and meeting the evolving needs of the industry. With ongoing investments in research and development and a focus on customer satisfaction, the company is well-positioned to continue its growth trajectory and maintain its reputation as a global leader in the valve manufacturing sector.In conclusion, Industrial Valves is a company that exemplifies excellence in valve manufacturing. With their commitment to innovation, quality, and customer satisfaction, they have established themselves as a trusted partner for industries across the globe. Continuously pushing boundaries and embracing technological advancements, Industrial Valves sets the bar high for others in the industry, solidifying their position as a leader in innovation and reliability.

Efficient and Environmentally-Friendly Heat Pump Cooling Systems: The Future of Home Cooling

Heat Pump Cooling Systems have been gaining popularity in the HVAC industry in recent years. These systems offer an innovative and energy-efficient way to cool homes and businesses, making them a popular choice for environmentally conscious consumers. One company at the forefront of this technology is {}. With a commitment to sustainability and cutting-edge innovation, {} has been a leader in the development and manufacturing of Heat Pump Cooling Systems for residential and commercial use.The company's Heat Pump Cooling Systems are designed to provide reliable and efficient cooling solutions for a wide range of applications. Whether it's a small residential property or a large commercial building, {}'s systems are tailored to meet the specific cooling needs of their customers.One of the main advantages of {}'s Heat Pump Cooling Systems is their high energy efficiency. Unlike traditional air conditioning systems that rely on electricity to generate cool air, heat pump systems transfer heat from one place to another, using significantly less energy in the process. This not only reduces the environmental impact of cooling, but also helps to lower energy bills for consumers.In addition to their energy efficiency, {}'s Heat Pump Cooling Systems are also known for their reliability and durability. The company's commitment to quality and performance means that customers can trust that their cooling systems will operate smoothly and efficiently for years to come.Furthermore, {} offers a range of options for customers to choose from, ensuring that there is a cooling solution to fit every need and budget. Whether it's a ductless mini-split system for a single room or a centralized system for a large commercial space, {} has the expertise and technology to provide a custom solution for their customers.Another key feature of {}'s Heat Pump Cooling Systems is their eco-friendly design. The company prioritizes sustainability in all aspects of their business, from manufacturing processes to product design. By choosing {}'s cooling systems, customers can feel good about reducing their carbon footprint and contributing to a cleaner, healthier planet.Furthermore, {} takes pride in its customer service and support. The company's team of experts is dedicated to guiding customers through the process of selecting, installing, and maintaining their Heat Pump Cooling Systems. With a focus on customer satisfaction, {} ensures that their customers receive the best possible experience from start to finish.With a growing emphasis on environmental responsibility and energy efficiency, {}'s Heat Pump Cooling Systems are poised to continue making an impact in the HVAC industry. As more and more consumers prioritize sustainability and cost savings, the demand for innovative cooling solutions like those offered by {} is expected to rise.In conclusion, {} is leading the way in the development and manufacturing of Heat Pump Cooling Systems that are energy-efficient, reliable, and environmentally friendly. With a commitment to quality, innovation, and customer satisfaction, the company is well-positioned to meet the growing demand for sustainable cooling solutions in the residential and commercial markets. As the HVAC industry continues to evolve, {} remains dedicated to providing cutting-edge technology and superior performance in their Heat Pump Cooling Systems.

Understanding the Drawbacks of Screw Pumps: A Comprehensive Analysis

Title: Overcoming Challenges: Understanding Screw Pump Disadvantages for Improved Industrial ApplicationsIntroduction:As industrial processes continue to evolve and become more complex, reliable and efficient pumping systems are crucial for the smooth operation of various industries. Screw pumps have emerged as a popular choice due to their ability to handle viscous fluids, high suction capabilities, and self-priming features. However, it is important to be aware of the potential disadvantages of screw pumps to ensure an informed decision for optimal industrial performance.Disadvantages of Screw Pumps:1. Limited Suitability for Low-Viscosity Liquids:Screw pumps are primarily designed to handle high-viscosity fluids, such as heavy oils, sludges, and emulsions. When used with low-viscosity liquids, the efficiency of screw pumps decreases significantly, leading to reduced performance and increased energy consumption. Manufacturers should consider alternative pump options for low-viscosity applications to achieve optimal results.2. Sensitivity to Abrasive Particles:Screw pumps are sensitive to abrasive particles present in fluids, which can result in increased wear and tear of the pump components. The continuous rotation of the screws causes abrasive particles to rub against the pump's surface, leading to reduced efficiency and potential failure. Utilizing additional filtration systems or opting for pumps with anti-abrasive coatings can help mitigate this issue.3. Maintenance Challenges:Screw pumps require regular maintenance to ensure consistent performance. The rotating components of these pumps are susceptible to wear, necessitating the replacement of parts such as seals, bushings, and bearing assemblies over time. Extending the life of these components can be achieved through proper lubrication, routine inspections, and promptly addressing any signs of wear or damage.4. Reduced Efficiency at High Speeds:While screw pumps offer excellent performance at moderate speeds, their efficiency decreases significantly when operated at high speeds. Power consumption and temperature rise proportionally with increasing rotational speed, resulting in decreased operational efficiency and potential overheating. Therefore, it is crucial for manufacturers to consider speed requirements and optimize pump selection accordingly.5. Space and Installation Constraints:Screw pumps tend to be larger in size compared to other pump types, which can pose challenges in terms of installation and space management. The larger dimensions can limit their applications in compact industrial settings, requiring sufficient space allocation for proper installation. Organizations need to assess their available space and evaluate the compatibility of screw pumps within their existing infrastructure.The Way Forward:To overcome the aforementioned disadvantages and make the most of screw pumps' potential, companies such as {} have implemented innovative solutions. By combining their extensive industry experience and advanced engineering techniques, they have successfully developed improved screw pump models that address these challenges.Company Introduction: {}With a strong commitment to research and development, {} has emerged as a leading manufacturer of reliable and efficient screw pump solutions. Their state-of-the-art manufacturing facilities utilize cutting-edge technologies to create high-performance pumps that cater to a wide range of industrial applications.By leveraging their expertise in design, engineering, and quality assurance, {} has introduced a new generation of screw pumps that mitigate the disadvantages associated with traditional models. These pumps incorporate advanced materials, enhanced filtration systems, and improved cooling mechanisms to overcome limitations and ensure optimum performance.To address the issue of limited suitability for low-viscosity liquids, {} has devised proprietary designs that optimize performance across a wider range of viscosities. This innovation allows businesses to utilize screw pumps effectively in applications involving fluids with diverse viscosity levels.To combat the sensitivity to abrasive particles, {} has implemented materials with superior hardness and resistance to abrasion in their pump components. This ensures prolonged service life and minimizes the risk of damage, significantly reducing downtime and maintenance requirements.Furthermore, {} has introduced efficient lubrication systems and enhanced cooling features in their screw pump designs. These refinements improve the pumps' efficiency, minimize temperature rise, and enhance overall operational reliability, even at high speeds.Conclusion:While screw pumps bring valuable advantages to the industrial pumping landscape, it is essential to be aware of their potential limitations. {} understands these disadvantages and has successfully engineered improved screw pump solutions that overcome these challenges. By investing in research, development, and innovative designs, manufacturers can optimize their pumping systems and achieve efficient and reliable operations in diverse industrial applications.

Effective Screw Pump Maintenance Tips for Longer Life and Performance

As the demand for efficient and reliable screw pump maintenance continues to rise in the industrial sector, it is crucial for companies to invest in high-quality and reputable maintenance services. With this growing need in mind, there is a company that stands out as a leader in providing top-notch screw pump maintenance solutions. [Company Name] is a globally recognized company that has been in the business of providing maintenance services for screw pumps for over 20 years. The company prides itself on its dedication to excellence, innovation, and customer satisfaction. With a team of highly trained and experienced professionals, [Company Name] has established itself as a trusted partner for industries seeking reliable screw pump maintenance solutions.One of the key factors that set [Company Name] apart from its competitors is its commitment to delivering personalized and tailor-made maintenance services to meet the unique needs of each client. The company understands that every screw pump system is different, and therefore requires a customized approach to maintenance. By taking the time to assess and understand the specific requirements of each client, [Company Name] is able to provide comprehensive and effective maintenance solutions that ensure optimal performance and longevity of the screw pumps.In addition to its personalized approach, [Company Name] also places a strong emphasis on using the latest technology and techniques to carry out maintenance services. The company invests in state-of-the-art equipment and tools, and its team is constantly trained and updated on the most advanced methods and best practices in screw pump maintenance. This dedication to staying at the forefront of the industry ensures that [Company Name] is able to deliver the highest quality of service to its clients.Moreover, [Company Name] is known for its quick and efficient response to maintenance requests. The company understands the critical role that screw pumps play in the operations of its clients, and therefore prioritizes fast and reliable service. Whether it is routine maintenance, emergency repairs, or troubleshooting, [Company Name] is committed to delivering timely and effective solutions to keep its clients' screw pumps running smoothly and efficiently.It is important to note that screw pumps are a vital component in a wide range of industrial applications, including wastewater treatment, oil and gas production, food processing, and more. As such, the proper maintenance of screw pumps is essential to ensure uninterrupted and reliable operations. With [Company Name]'s expertise and dedication to superior maintenance services, industries can have the peace of mind knowing that their screw pump systems are in good hands.In conclusion, [Company Name] has firmly established itself as a leading provider of screw pump maintenance solutions, thanks to its commitment to excellence, innovation, and customer satisfaction. With its personalized approach, use of advanced technology, and quick response, [Company Name] continues to set the standard for high-quality screw pump maintenance services. As the demand for reliable maintenance solutions for screw pumps continues to grow, [Company Name] is poised to remain at the forefront of the industry, serving as a trusted partner for industries seeking top-notch maintenance services.

High-Quality Rotor Screw Pump for Efficient Pumping

Rotor Screw Pump, a leading manufacturer of industrial pumping solutions, has recently launched a new series of screw pumps designed to meet the growing demand for reliable and efficient pumping systems in the global market.The new series of screw pumps are the result of extensive research and development efforts, aimed at providing customers with innovative pumping solutions that deliver superior performance and durability. The company's commitment to excellence is reflected in the quality and reliability of their products, making them the preferred choice for a wide range of industrial applications.With a legacy of over 50 years in the industry, Rotor Screw Pump has earned a solid reputation for delivering high-quality pumping solutions that meet the diverse needs of their customers. The company's state-of-the-art manufacturing facilities and advanced engineering capabilities ensure that they stay ahead of the curve in terms of product innovation and performance.The new series of screw pumps feature a robust design that allows for seamless operation even in the most demanding environments. The pumps are equipped with advanced technologies that optimize efficiency and reduce energy consumption, making them an eco-friendly choice for businesses looking to minimize their environmental footprint.In addition to their superior performance, the new series of screw pumps are also designed for easy installation and maintenance, helping customers minimize downtime and maximize productivity. The pumps are built to withstand the rigors of industrial operations, delivering reliable performance day in and day out."We are excited to introduce our new series of screw pumps to the global market," said a spokesperson for Rotor Screw Pump. "These pumps represent the culmination of our decades of experience and expertise in the industry, and we are confident that they will set a new standard for performance and reliability in industrial pumping."The company's dedication to customer satisfaction is evident in their comprehensive support services, which include technical assistance, maintenance, and repair. Rotor Screw Pump's team of experts is committed to helping customers find the right pumping solutions for their specific needs, and ensuring that their equipment operates at peak efficiency at all times.With a strong focus on innovation and continuous improvement, Rotor Screw Pump is poised to remain at the forefront of the industry, providing customers with cutting-edge pumping solutions that deliver exceptional value. The company's new series of screw pumps is a testament to their ongoing commitment to excellence and their determination to meet the evolving needs of the market.As the global demand for effective pumping solutions continues to grow, Rotor Screw Pump is well positioned to capitalize on the opportunities that lie ahead. With their proven track record of delivering high-quality products and unparalleled customer support, the company is set to solidify its position as a trusted partner for businesses seeking reliable and efficient pumping solutions.The launch of the new series of screw pumps marks the beginning of an exciting new chapter for Rotor Screw Pump, as the company looks to expand its presence in key markets around the world. With their dedication to innovation and customer satisfaction, the company is well positioned to make a significant impact in the global pumping industry.

What Is a Positive Displacement Pump and How Does It Work?

Positive Displacement Pump Means Enhanced Efficiency and Reliability for Industrial ApplicationsIn the fast-paced world of industrial manufacturing, reliability and efficiency are critical components for success. Companies across various industries are constantly seeking innovative solutions to streamline their production processes and maximize their output. One such solution that has been gaining widespread popularity in recent years is the positive displacement pump. These pumps are designed to deliver a consistent flow of fluid at a specific rate, making them an ideal choice for a wide range of industrial applications. When it comes to positive displacement pumps, there is one company that stands out from the rest – {}. With a strong focus on quality and innovation, {} has become a leading supplier of positive displacement pumps to industries all around the world.One of the key advantages of positive displacement pumps is their ability to maintain a steady flow of fluid regardless of changes in pressure or viscosity. This makes them highly versatile and suitable for applications such as chemical processing, food and beverage production, oil and gas extraction, and much more. By utilizing positive displacement pumps, companies can ensure a consistent output while minimizing the risk of downtime and production delays.Another major benefit of positive displacement pumps is their high level of efficiency. Unlike other types of pumps that rely on centrifugal force to generate flow, positive displacement pumps operate by trapping and displacing a specific volume of fluid with each cycle. This results in a more precise and controlled flow, leading to reduced energy consumption and lower operating costs. With sustainability becoming an increasingly important consideration for businesses, the efficiency of positive displacement pumps has made them a popular choice for companies looking to reduce their environmental impact.In addition to their efficiency and reliability, positive displacement pumps are also known for their ability to handle a wide range of fluids, including viscous, abrasive, and shear-sensitive materials. This makes them suitable for a diverse array of industrial processes, from transferring thick sludges to delicate emulsions. With the right design and materials of construction, positive displacement pumps can be customized to meet the specific needs of each application, providing companies with a highly adaptable solution for their fluid handling requirements.As a leading supplier of positive displacement pumps, {} has played a pivotal role in driving the adoption of this technology across various industries. The company's extensive experience and expertise in pump manufacturing have enabled them to develop a diverse range of positive displacement pumps that cater to the unique needs of their customers. By leveraging advanced engineering techniques and rigorous quality control measures, {} has been able to deliver pumps that offer exceptional performance, durability, and long-term value.In summary, positive displacement pumps have emerged as a game-changing technology for industrial fluid handling, offering enhanced efficiency, reliability, and versatility. With {} at the forefront of this industry, companies can expect to benefit from cutting-edge pump solutions that optimize their production processes and drive overall success. As the demand for reliable and efficient fluid handling solutions continues to grow, positive displacement pumps are poised to play a crucial role in shaping the future of industrial manufacturing.