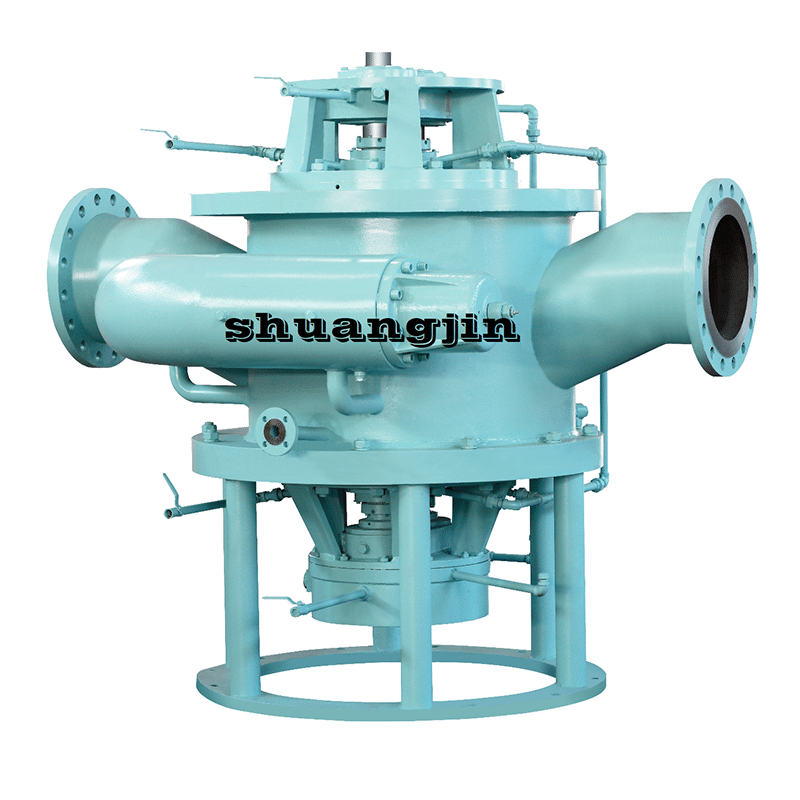

High-performance Multiphase Pump for Efficient Fluid Handling

By:Admin

In the fast-paced and ever-evolving world of oil and gas production, the need for efficient and effective multiphase pumping technology has never been greater. The demands of increased production from unconventional resources, the challenges of offshore and subsea operations, and the need for more cost-effective and environmentally friendly solutions have all combined to drive the development of innovative multiphase pumping solutions.

One company at the forefront of this technological revolution is {}. With a strong commitment to research and development, practical engineering, and customer focus, {} has become a leader in multiphase pump technology and has been instrumental in driving the adoption of multiphase pumping systems in the oil and gas industry.

{}’s multiphase pump systems are designed to handle a wide range of fluid mixtures, including gas, oil, and water, in a single pipeline. This revolutionary technology eliminates the need for separate gas and liquid handling equipment, significantly reducing capital and operating costs for oil and gas producers. In addition, {}’s multiphase pumping systems are capable of delivering increased production rates, improved efficiency, and enhanced flexibility for a variety of applications, including onshore and offshore fields, subsea developments, and heavy oil and oil sands production.

The technology behind {}’s multiphase pump systems is based on a combination of advanced engineering, cutting-edge materials, and innovative design. By leveraging the latest advancements in computational fluid dynamics, finite element analysis, and additive manufacturing, {}’s engineers have been able to optimize the performance and reliability of their multiphase pumping solutions. In addition, {}’s multiphase pump systems are built to withstand the harsh operating conditions of the oil and gas industry, including high pressures, extreme temperatures, and corrosive environments, ensuring long-term performance and durability.

{}’s commitment to customer focus is evident in the company’s comprehensive approach to multiphase pump technology. {}’s team of experts works closely with oil and gas producers to understand their specific challenges and requirements, providing tailored solutions to maximize efficiency and productivity. Furthermore, {} offers a full range of services, including installation, commissioning, training, and ongoing support, to ensure that their customers are able to fully leverage the benefits of multiphase pumping technology.

The impact of {}’s multiphase pump technology on the oil and gas industry has been significant. By enabling oil and gas producers to increase production rates, optimize reservoir recovery, and reduce capital and operating costs, {}’s multiphase pump systems have become essential tools for maximizing the value of oil and gas assets. In addition, the environmentally friendly nature of multiphase pumping, which reduces emissions and minimizes the need for separate gas handling facilities, is in line with the industry's increasing focus on sustainability and responsible resource development.

Looking ahead, {} is committed to continuing the development of multiphase pump technology, with ongoing investments in research and development, engineering innovation, and customer support. With the demand for multiphase pumping solutions expected to grow as oil and gas producers seek to maximize the potential of unconventional resources and improve operational efficiency, {} is well-positioned to play a key role in the future of the oil and gas industry.

In conclusion, {}’s multiphase pump technology has revolutionized oil and gas production by providing cost-effective, efficient, and environmentally friendly solutions for handling complex fluid mixtures. With a focus on research and development, practical engineering, and customer support, {} has become a leader in multiphase pump technology and is poised to continue driving innovation and value for the oil and gas industry.

Company News & Blog

Professional Screw Pump Installation Services for Industrial needs

Screw Pump Installation Boosts Efficiency at XYZ IndustriesXYZ Industries, a leading manufacturer of industrial equipment, has recently completed the installation of state-of-the-art screw pumps at its manufacturing facility in [location]. The new screw pumps are expected to significantly enhance the company's production efficiency and contribute to its ongoing commitment to sustainable manufacturing practices.The screw pumps, which were manufactured by a reputable pump supplier, are designed to handle a wide range of industrial fluids, including water, oil, and chemicals. The installation of these pumps represents a major investment by XYZ Industries in upgrading its production infrastructure to meet the growing demands of its customers and to stay ahead of the competition.The decision to install the new screw pumps is part of XYZ Industries' long-term strategy to optimize its manufacturing processes and reduce its environmental impact. By investing in the latest pump technology, the company aims to minimize energy consumption and waste generation while maintaining high levels of productivity and product quality."We are pleased to announce the successful installation of the new screw pumps at our facility," said [spokesperson], CEO of XYZ Industries. "This investment reflects our commitment to innovation and sustainability, and we believe that it will have a positive impact on both our production efficiency and our environmental performance."The installation of the screw pumps was carried out by a team of experienced engineers and technicians, who worked closely with XYZ Industries' production staff to ensure a smooth and efficient integration of the new equipment into the existing manufacturing processes. The installation process was completed ahead of schedule, allowing the company to resume full production capacity without any significant disruptions.The new screw pumps are expected to deliver several key benefits for XYZ Industries, including improved reliability, higher flow rates, and lower maintenance requirements compared to the older pumps they replaced. This is anticipated to result in significant cost savings over the long term, as well as a reduced risk of unplanned downtime and production delays.In addition to the tangible operational benefits, the installation of the new screw pumps aligns with XYZ Industries' broader corporate responsibility goals. The company is committed to implementing sustainable practices across its operations, and the use of advanced pump technology is an important step towards achieving its environmental targets."Our investment in the new screw pumps is just one example of our ongoing efforts to reduce our environmental footprint and operate more efficiently," added [spokesperson]. "We believe that by taking proactive steps to improve our production processes, we can make a meaningful contribution to a more sustainable future."Looking ahead, XYZ Industries plans to continue exploring opportunities for further advancements in its manufacturing infrastructure, including the potential adoption of other innovative technologies to enhance its operations. The company remains firmly committed to driving continuous improvement and staying at the forefront of industrial innovation.In conclusion, the successful installation of the new screw pumps at XYZ Industries' manufacturing facility marks a significant milestone in the company's journey towards greater efficiency and sustainability. By leveraging the latest pump technology, XYZ Industries aims to strengthen its competitive position and make a positive impact on the environment, while meeting the evolving needs of its customers and stakeholders.

HVAC Pump Servicing: Expert Maintenance for Your System

Pump Servicing Company Continues to Provide Quality Maintenance and RepairsWith a strong commitment to providing exceptional servicing for pumps and pumping equipment, Pump Servicing Company has been a leader in the industry for over [X] years. The company has built a reputation for delivering quality maintenance and repair services to a wide range of clients, including industrial facilities, water treatment plants, and commercial buildings.As a leading provider of pump servicing, Pump Servicing Company offers a comprehensive range of maintenance and repair solutions to keep pumps functioning at their best. The company's team of experienced technicians is well-equipped to handle various types of pumps, including centrifugal, submersible, and positive displacement pumps. With a focus on delivering reliable and efficient servicing, Pump Servicing Company is dedicated to helping clients minimize downtime and maximize the lifespan of their pumping equipment.One of the key strengths of Pump Servicing Company is its commitment to staying up-to-date with the latest technologies and industry best practices. The company invests in ongoing training and development for its technicians to ensure that they are equipped with the knowledge and skills to address the evolving needs of clients. This dedication to continuous improvement has enabled Pump Servicing Company to stay ahead of the curve and provide innovative solutions to its clients.In addition to its focus on technical expertise, Pump Servicing Company places a strong emphasis on customer service. The company understands the importance of timely and reliable servicing, and its team is committed to delivering a seamless experience for clients. Whether it's a routine maintenance visit or an emergency repair, Pump Servicing Company strives to provide responsive and attentive service to meet the needs of its clients.Pump Servicing Company's dedication to excellence is reflected in its use of high-quality parts and materials for all servicing and repairs. The company has developed strong relationships with leading suppliers to ensure that clients receive the best components for their pumping equipment. This commitment to quality not only enhances the performance and reliability of the pumps but also contributes to the overall longevity of the equipment.As part of its ongoing efforts to expand its service offerings, Pump Servicing Company has recently introduced a preventive maintenance program. This proactive approach to pump servicing focuses on regular inspections, testing, and adjustments to identify and address potential issues before they escalate. By taking a preventive maintenance approach, Pump Servicing Company aims to help clients reduce the likelihood of unexpected breakdowns and costly repairs.Furthermore, Pump Servicing Company is committed to environmental sustainability and compliance with industry regulations. The company adheres to strict environmental standards and best practices in its servicing and repair processes to minimize the impact on the environment. With a strong focus on safety and environmental responsibility, Pump Servicing Company is dedicated to operating in a manner that aligns with the highest industry standards.Looking ahead, Pump Servicing Company is focused on further expanding its service capabilities and enhancing its presence in the market. The company remains committed to delivering exceptional pump servicing solutions to meet the diverse needs of its clients across various industries. With a strong foundation of technical expertise, customer service excellence, and a commitment to quality, Pump Servicing Company is well-positioned to continue its leadership in the pump servicing industry.

Best Tips for Efficient Heating and Cooling in Your Home

In today's rapidly changing world, the need for energy efficient solutions has become more important than ever. One company that has been at the forefront of this movement is {}. With a focus on innovative technology and a commitment to sustainability, {} has been leading the way in providing heating and cooling solutions that are not only efficient, but also environmentally friendly.As the demand for energy efficient heating and cooling systems continues to grow, {} has been at the forefront of developing cutting-edge solutions that meet the needs of both residential and commercial customers. With a wide range of products and services, {} has positioned itself as a leader in the industry, providing high-quality, reliable and cost-effective solutions that help customers reduce their energy consumption and lower their carbon footprint.At the heart of {}'s success is their dedication to innovation and technology. By constantly investing in research and development, {} has been able to stay ahead of the curve and deliver state-of-the-art products that are not only more efficient, but also more reliable and durable. Whether it's a new air conditioning unit for a home or a large-scale heating system for a commercial building, {} has the expertise and experience to deliver the right solution for any customer.In addition to their focus on innovation, {} is also committed to sustainability. By using environmentally friendly materials and manufacturing processes, {} is able to produce products that have a minimal impact on the environment. This commitment to sustainability has not only helped {} reduce its own carbon footprint, but has also enabled customers to make a positive environmental impact by choosing {}'s products and services.Another key aspect of {}'s success is their dedication to customer service. With a team of highly trained and experienced professionals, {} is able to provide the highest level of service and support to their customers. From initial consultation and product selection to installation and maintenance, {} is with their customers every step of the way, ensuring that they have a positive experience and that their heating and cooling systems are running at peak performance.Looking to the future, {} is poised to continue leading the way in heating and cooling solutions, with a focus on sustainable, energy efficient products and a commitment to customer satisfaction. By staying ahead of the curve and continually innovating, {} is well positioned to meet the evolving needs of the market and to continue providing high-quality solutions for many years to come.In conclusion, {} has established itself as a leader in the heating and cooling industry, with a strong focus on innovation, technology, sustainability, and customer service. As the demand for energy efficient solutions continues to grow, {} is well positioned to continue providing cutting-edge products and services that meet the needs of residential and commercial customers alike.

Common Disadvantages of Screw Pumps You Should Know

Screw Pump Disadvantages Screw pumps have been widely used in various industries for their ability to handle a wide range of fluids, including high-viscosity liquids, and for their efficiency in delivering a constant flow. However, despite their numerous advantages, screw pumps also come with their own set of disadvantages that can impact their performance and efficiency.One of the main disadvantages of screw pumps is their susceptibility to abrasive wear. The rotating screws and the pump casing are subject to continuous contact with the pumped fluid, which can contain abrasive particles. Over time, this can lead to wear and erosion of the pump components, ultimately reducing the pump's efficiency and lifespan. Another drawback of screw pumps is their sensitivity to changes in fluid viscosity. While screw pumps are known for their ability to handle high-viscosity fluids, they can struggle to maintain a consistent flow when the viscosity of the pumped fluid varies. This can result in fluctuations in the pump's performance and the quality of the output, making it less reliable in certain applications.Additionally, the design of screw pumps makes them more prone to clogging compared to other types of pumps. The tight clearances between the rotating screws and the pump casing can lead to the accumulation of debris and solids, which can obstruct the flow of the pumped fluid and cause operational issues. This can be a significant drawback in industries where the pumped fluids may contain a high concentration of solids or impurities.Furthermore, screw pumps are known for their relatively high maintenance requirements. The intricate design of the pump and the close tolerances between the rotating components necessitate regular maintenance and repairs to ensure optimal performance. This can result in higher operating costs and downtime, particularly in industrial settings where continuous operation is crucial.Despite these disadvantages, several companies, including {} continue to use screw pumps in their operations. Founded in 1999, {} has established itself as a leading provider of pumping solutions for a wide range of industries, including oil and gas, marine, and industrial applications. The company's extensive product line includes a variety of pump types, including screw pumps, centrifugal pumps, and diaphragm pumps, among others.{}'s screw pumps are renowned for their robust construction, high efficiency, and reliable performance, making them a popular choice for handling challenging fluids in demanding environments. The company's dedication to innovation and quality has allowed it to develop state-of-the-art screw pumps that address many of the traditional disadvantages associated with this pump type.For instance, {}'s screw pumps are equipped with advanced materials and coatings that enhance their resistance to abrasive wear, extending their lifespan and reducing maintenance requirements. The company's engineering team has also implemented innovative design features to mitigate the effects of fluid viscosity variations, ensuring consistent and reliable performance across a wide range of operating conditions.In addition, {}'s screw pumps are designed with larger clearances and anti-clogging features to minimize the risk of debris accumulation and blockages, making them well-suited for handling fluids with high solids content. This has made {}'s screw pumps a preferred choice for industries where the pumping of abrasive or viscous fluids is a common requirement.Moreover, {} offers comprehensive aftermarket support and a global network of service centers to provide timely maintenance and repair services for its screw pumps, minimizing downtime and maximizing the reliability of its pumping solutions. With a commitment to customer satisfaction and a focus on continuous improvement, {} has positioned itself as a trusted partner for companies seeking reliable and efficient pumping solutions.In conclusion, while screw pumps have their own set of disadvantages, companies like {} are continuously innovating and improving the design and performance of these pumps to overcome these challenges. By addressing issues such as abrasive wear, fluid viscosity sensitivity, clogging, and maintenance requirements, {} has demonstrated the potential for screw pumps to remain a valuable and reliable pumping solution for a wide range of industries.

Innovative Impeller Pump Design Revolutionizes Industrial Fluid Transfer

New Screw Impeller Pump Revolutionizes Industrial PumpingIndustrial processes require highly efficient and reliable pumping systems that can handle large volumes of liquids and solids. And, I am pleased to announce that the Screw Impeller Pump, produced by a leading manufacturer in the industry, delivers exactly that. The pump represents a technological revolution in the world of industrial pumping systems, and it has proved to be a game changer in harsh industrial environments across the globe.The Screw Impeller Pump, also known as the twin-screw pump, is a highly advanced pump that works on a unique screw impeller technology. The pump produces a smooth fluid flow while handling fluids with high viscosity, which is important in a variety of industrial applications. This is achieved by the co-rotating screws with a helical rotation that move precisely together and trap the fluid within the pump's cavity, moving it along steadily and continuously.The pump has been designed after decades of research and development on screw impeller technology. The pump manufacturer has implemented a patented technology that ensures that the Screw Impeller Pump performs exceptionally well in handling abrasive materials and viscous liquids that other pumps would typically struggle with. The technology involves an improved screw profile that helps to produce a more consistent flow rate, higher efficiency, and lower noise levels.To ensure that the Screw Impeller Pump meets the rigorous requirements of different industrial applications worldwide, the manufacturer has put a lot of effort into its construction. The pump features sturdy construction materials that resist wear, corrosion, and high-pressure surges. This makes it ideal for pumping fluids such as petroleum products, chemicals, paint, lubricants, and food products. The hard-wearing construction also ensures that the pump operates for longer periods without incurring downtime.The Screw Impeller Pump also comes with a highly advanced sealing system that prevents leaks, ensures that the pump's operation is smooth and stable, and reduces maintenance costs. This has been achieved by using a specially designed shaft seal that coats the shaft's surface with a low-friction coating that reduces friction. This feature significantly reduces the need for frequent maintenance and replacements.Another notable feature of the Screw Impeller Pump is its versatility. The pump can handle different types of fluids and materials and works well even in harsh industrial environments. It is also energy-efficient, which translates to reduced energy costs and lower carbon emissions. The pump consumes less energy to produce the same fluid volume as compared to conventional pumps, making it a great environmentally friendly alternative to traditional pumps.In addition to its excellent features, the Screw Impeller Pump delivers consistently high performance, thanks to its advanced monitoring and control systems. The manufacturer has incorporated advanced sensors and control systems that help to monitor the pump's performance in real-time. This ensures that the pump operates at its optimal level while preventing downtime and costly machine breakdowns.In summary, the Screw Impeller Pump is a high-performance industrial pump that has been designed to deliver exceptional performance in handling different types of fluids with various viscosities and solids. The pump's robust construction, advanced sealing system, and energy-efficient design make it a great addition to industrial process lines. Its versatility, consistency, and low maintenance costs make it a cost-effective solution to many industrial pumping challenges.As a renowned pump distributor, we are proud to offer this innovative pump to our clients across various industrial sectors. Get in touch with our experts today to learn more about the Screw Impeller Pump and how you can incorporate it into your industrial processes.

The Versatile Applications of Screw Pumps

Industrial pumps are an essential component in many manufacturing and processing operations. One type of pump that is widely used in various industries is the screw pump. Screw pumps are positive displacement pumps that use rotating screws to move fluid or liquid along the screw's axis. These pumps are known for their ability to handle a wide range of viscosity and are often used in applications where high pressure and high flow rates are required.One of the leading manufacturers of screw pumps is {}, a company that prides itself on its innovative and high-quality pump solutions. With a strong focus on research and development, {} has been able to provide efficient and reliable screw pump products to its customers worldwide.The uses of screw pumps are varied, and they can be found in a wide range of industries, including oil and gas, chemical processing, food and beverage, and water treatment.In the oil and gas industry, screw pumps are commonly used for the transfer of crude oil and refined products. With their ability to handle high viscosity fluids, screw pumps are well-suited for moving heavy oils and other petroleum products from one location to another.In chemical processing plants, screw pumps are used for the transfer of acids, solvents, and other corrosive chemicals. The robust design of screw pumps makes them a reliable choice for handling aggressive and potentially hazardous substances.In the food and beverage industry, screw pumps are utilized for the transfer of various liquid products, such as dairy, juice, and syrups. The hygienic design of screw pumps makes them suitable for use in food processing applications, where cleanliness and sanitation are paramount.In water treatment facilities, screw pumps are used for the transfer of wastewater, sludge, and other fluids. The ability of screw pumps to handle high solids content and abrasive materials makes them a popular choice for these demanding applications.One of the key advantages of screw pumps is their ability to operate at low pulsation levels, which results in a smooth and steady flow of fluid. This makes them suitable for use in applications where precise and consistent fluid transfer is required.Additionally, screw pumps are known for their high efficiency and low maintenance requirements, making them a cost-effective choice for many industrial applications.With their versatility and reliability, it is no wonder that screw pumps are an essential component in various industries. As technology and manufacturing processes continue to evolve, the demand for high-performing pumps like screw pumps is expected to grow.As a leading manufacturer of screw pumps, {} has been at the forefront of delivering innovative pump solutions to its customers. With a strong focus on quality and performance, {} has earned a reputation for providing reliable and efficient screw pumps that meet the needs of diverse industries.The company's commitment to research and development has enabled it to continually improve and innovate its screw pump products, ensuring that they remain at the forefront of pump technology.With a global presence and a dedication to customer satisfaction, {} is well-positioned to meet the growing demand for screw pumps in the industrial sector. Whether it is for oil and gas, chemical processing, food and beverage, or water treatment, {} has the expertise and capabilities to deliver high-quality screw pump solutions to its customers.In conclusion, the uses of screw pumps are diverse and vital to many industries, and with a company like {} leading the way in pump innovation, the future looks bright for this essential piece of industrial equipment.

High-Quality Screw Pump Catalogue for Industrial Applications

Screw Pump Catalogue Released by Leading Industrial Company{} is proud to announce the release of their highly anticipated Screw Pump Catalogue, showcasing a wide range of innovative and efficient screw pump solutions for industrial applications. The company, known for its expertise in providing high-quality industrial equipment, continues to set the standard for reliable and cutting-edge solutions in the industry.The newly released Screw Pump Catalogue features a comprehensive lineup of screw pump products designed to meet the diverse needs of various industrial sectors. From oil and gas to chemical processing, marine, and power generation, {} offers a wide range of screw pump options to cater to the specific requirements of different applications.One of the standout features of the screw pumps showcased in the catalogue is their exceptional performance and reliability. With a focus on precision engineering and advanced technology, {} ensures that each screw pump meets the highest standards for efficiency, durability, and long-term performance. This commitment to quality has earned {} a reputation as a trusted partner for industrial businesses seeking top-of-the-line pump solutions.The catalogue also highlights the company's dedication to innovation and customization. Customers can choose from a range of options, including different materials, sizes, flow rates, and pressure capabilities to tailor the screw pumps to their unique operational needs. With {}’s in-depth knowledge and experience in the industry, customers can rely on the company to provide expert guidance in selecting the most suitable screw pump for their specific requirements.In addition to the wide array of standard screw pump offerings, {} also provides custom engineering and design services for specialized applications. This customization capability sets {} apart as a versatile and adaptable partner for businesses with unique pump requirements. The company's team of engineers and technical experts work closely with customers to develop tailored solutions that address specific challenges and deliver optimal performance.Furthermore, {} takes pride in its commitment to customer satisfaction and support. With a global network of service centers and technical professionals, the company offers comprehensive after-sales support, including maintenance, repairs, and spare parts supply. Customers can have peace of mind knowing that {} is dedicated to ensuring the ongoing reliability and longevity of their screw pump investments.The release of the Screw Pump Catalogue solidifies {}’s position as a leading provider of industrial pump solutions. With a strong focus on quality, innovation, and customer-centric approach, {} continues to empower businesses across diverse industries with reliable and high-performing screw pump technologies.About {}:{} is a renowned industrial company specializing in the design, manufacturing, and supply of high-quality pump solutions for a wide range of industrial applications. With a strong commitment to excellence and innovation, the company has established itself as a trusted partner for businesses seeking reliable and efficient pump technologies. Through its comprehensive product offerings, customization capabilities, and dedicated customer support, {} continues to lead the way in delivering cutting-edge pump solutions to meet the evolving needs of industrial sectors worldwide.In conclusion, the release of the Screw Pump Catalogue by {} represents a significant milestone for the company and the industrial sector as a whole. With its extensive range of high-quality screw pump solutions and unwavering commitment to customer satisfaction, {} sets a new standard for excellence and reliability in the industry. Businesses looking for best-in-class pump technologies can rely on {} to deliver top-notch products and support for their operational success.

Benefits of Positive Displacement Screw Pumps for Industrial Applications

Positive Displacement Screw Pump is a critical component for various industries, from oil and gas to food and beverage, providing a reliable and efficient method for fluid transfer. One company at the forefront of this technology is {Company Name}, a leading manufacturer of industrial pumps and systems.With a history dating back several decades, {Company Name} has built a reputation for delivering high-quality pumping solutions to a global customer base. The company's expertise in Positive Displacement Screw Pump technology has positioned them as a trusted partner for many industries, providing innovative and reliable pumping solutions for a wide range of applications.Positive Displacement Screw Pumps are known for their ability to handle a variety of fluids, from thin liquids to highly viscous substances. This versatility makes them an ideal choice for industries where consistent and precise fluid transfer is essential. {Company Name} has leveraged their engineering expertise to develop cutting-edge screw pump technology that meets the unique needs of their clients.One of the key advantages of {Company Name}'s Positive Displacement Screw Pump is its ability to deliver a consistent flow rate and pressure, ensuring reliable performance in demanding operating conditions. Whether it's transferring crude oil in the energy sector or handling delicate food products in the food and beverage industry, these pumps are designed to provide efficient and precise fluid transfer.In addition to their performance capabilities, {Company Name}'s Positive Displacement Screw Pump is also engineered for durability and longevity. With robust construction and high-quality materials, these pumps are built to withstand the rigors of continuous operation, reducing downtime and maintenance costs for their customers.Furthermore, {Company Name} takes pride in their commitment to innovation and continuous improvement. Their team of engineers and technical experts are dedicated to developing new and improved pumping solutions, ensuring that their Positive Displacement Screw Pump remains at the forefront of industry standards and customer expectations.{Company Name} also understands the importance of customer support and service. They are committed to providing comprehensive technical assistance, spare parts, and maintenance services to ensure that their customers' pumping systems operate at peak performance. This dedication to customer satisfaction has earned {Company Name} a loyal and satisfied customer base around the globe.In conclusion, {Company Name} has established itself as a leader in the field of Positive Displacement Screw Pump technology, offering innovative, reliable, and efficient pumping solutions for a variety of industries. With a focus on performance, durability, and customer support, {Company Name} continues to set the standard for pumping systems, meeting the evolving needs of their clients and contributing to the success and efficiency of their operations.

Screw Pump vs. Centrifugal Pump: Understanding the Difference for Your Industrial Application

Screw pumps and centrifugal pumps are both widely used in industrial applications for the movement of fluids. Each has its own distinct advantages and disadvantages, and understanding the differences between the two can help businesses make informed decisions about which type of pump is best suited for their particular needs.A screw pump, as the name suggests, operates by using one or more screws to move the fluid through the pump. This type of pump is known for its ability to handle high viscosity fluids and for its gentle pumping action, which makes it ideal for handling shear-sensitive materials. The design of the screws also allows for a continuous, non-pulsating flow, which can be beneficial in certain applications.On the other hand, a centrifugal pump operates by using a rotating impeller to create a centrifugal force that moves the fluid through the pump. This type of pump is known for its high flow rate and ability to handle large volumes of fluid. Centrifugal pumps are also generally easier to install and maintain than screw pumps, making them a popular choice for many industrial applications.In terms of efficiency, screw pumps are generally more efficient than centrifugal pumps when it comes to handling high viscosity fluids. This is because the screw pump's design allows for a more continuous and smooth flow, whereas the impeller in a centrifugal pump can struggle with thicker fluids. However, centrifugal pumps are generally more efficient than screw pumps when it comes to handling lower viscosity fluids and are often the preferred choice for applications where high flow rates are required.Another key difference between screw pumps and centrifugal pumps is their ability to handle solid materials. Screw pumps are generally better suited for handling solids, as the design of the screws allows for the movement of larger particles without clogging. In contrast, centrifugal pumps can struggle with solids and are typically not recommended for applications where solid materials are present.In terms of cost, centrifugal pumps are generally less expensive to purchase and install than screw pumps. They also tend to have lower maintenance costs, making them a more cost-effective option for many businesses. However, the higher efficiency of screw pumps when handling high viscosity fluids can result in long-term cost savings in terms of energy consumption.In conclusion, both screw pumps and centrifugal pumps have their own distinct advantages and disadvantages, and the choice between the two will depend on the specific requirements of each individual application. Companies should carefully consider factors such as the viscosity of the fluids being handled, the presence of solid materials, and the required flow rates when deciding which type of pump is best suited for their needs.As a leading pump manufacturer, {} offers a wide range of both screw pumps and centrifugal pumps to meet the diverse needs of our customers. Our team of experts can work closely with businesses to determine the most suitable pump for their specific application, ensuring efficient and reliable fluid movement. With a commitment to quality and innovation, {} is dedicated to providing industry-leading pumping solutions for businesses across various industries.

Three-screw Pump: a versatile and efficient pump option

The leading manufacturer and supplier of industrial pumps, known for its innovative and high-quality products, has recently unveiled its latest addition to its product line - the SN Series Three-Screw Pump. The new pump is set to revolutionize the industrial pumping industry with its advanced features and superior performance.The SN Series Three-Screw Pump is designed to meet the demanding requirements of various industries, including oil and gas, chemical, and marine. It features a compact and rugged design, making it suitable for use in harsh and demanding environments. The pump is also equipped with high-performance three-screw technology, which ensures smooth and efficient operation.One of the key highlights of the SN Series Three-Screw Pump is its exceptional reliability and durability. The pump is engineered to withstand the rigors of industrial applications, providing long-lasting performance and reducing maintenance costs. Its robust construction and high-quality materials ensure that it can operate continuously under extreme conditions without compromising its performance.In addition, the pump offers exceptional versatility, making it suitable for a wide range of applications. Its high flow capacity and low noise levels make it ideal for pumping various types of fluids, including viscous liquids, high-temperature fluids, and abrasive slurries. The pump's ability to handle a wide range of viscosities and temperatures makes it a versatile solution for diverse industrial pumping needs.The SN Series Three-Screw Pump is also designed with ease of maintenance in mind. Its simple and accessible design allows for quick and hassle-free maintenance, minimizing downtime and maximizing productivity. This is especially valuable for industries that rely on continuous operation and cannot afford extended periods of equipment downtime.Furthermore, the pump is equipped with advanced safety features to ensure reliable and secure operation. It complies with industry standards and regulations, providing peace of mind for operators and ensuring the protection of personnel and equipment.With the launch of the SN Series Three-Screw Pump, the company further solidifies its position as a leading provider of innovative and high-quality industrial pumps. The pump's advanced features and superior performance are a testament to the company's commitment to delivering cutting-edge solutions that meet the evolving needs of its customers.The company has a long-standing reputation for excellence in the industrial pumping industry. With a rich history of delivering reliable and high-performance products, it has established itself as a trusted partner for numerous industries worldwide. The launch of the SN Series Three-Screw Pump is a testament to the company's relentless pursuit of innovation and its dedication to exceeding customer expectations.The company's extensive experience and expertise in engineering and manufacturing industrial pumps have enabled it to develop the SN Series Three-Screw Pump to the highest standards of quality and performance. Its state-of-the-art production facilities and rigorous quality control processes ensure that each pump meets the company's stringent performance and reliability standards.In conclusion, the launch of the SN Series Three-Screw Pump represents a significant milestone for the company and the industrial pumping industry as a whole. With its advanced features, superior performance, and unmatched reliability, the pump is set to redefine the standards of industrial pumping and set new benchmarks for efficiency, durability, and versatility. As the company continues to push the boundaries of innovation, it remains a trusted partner for industries seeking reliable and high-performance pumping solutions.